English (GB)

5

3.3 Storage

To prevent water, dust, etc. from entering the pump, all openings

must be covered until pipes are connected. Apply a suitable

antirust agent on all machined, non-coated surfaces.

The antirust agent must meet these requirements:

• It must not attack rubber parts.

• It must be easy to remove.

• It must be applied according to the instructions of the

manufacturer.

If the pump must be stored for more than six months before start-

up, it must be protected against corrosion and damage:

1. Remove the stuffing box packing.

2. Spray the interior part of the pump case and the stuffing box

with a water-soluble type of antirust agent.

3. If the pump has not been connected to the pipework, cover

the pump suction and discharge flanges with full natural

rubber gasket material, and blank off these openings with

metal blanking flanges. Use at least four bolts for fastening.

4. Cover the opening of the stuffing box with a non-hygroscopic

tape. The stuffing box gland may be left on the pump shaft,

but must be wired or otherwise securely fastened in position.

5. Coat all exposed painted surfaces with an antirust agent that

can be readily removed with a petroleum distillate product.

6. Make sure that all exposed painted surfaces are dry, clean

and free of grease and other contaminates.

7. Cover the pump with a weather-resistant cover of waterproof

paper or plastic material to protect it against dirt and dust.

8. Inspect the pump at regular intervals during storage.

9. Rotate the shaft by hand every four to six weeks to prevent

pitting of the bearings.

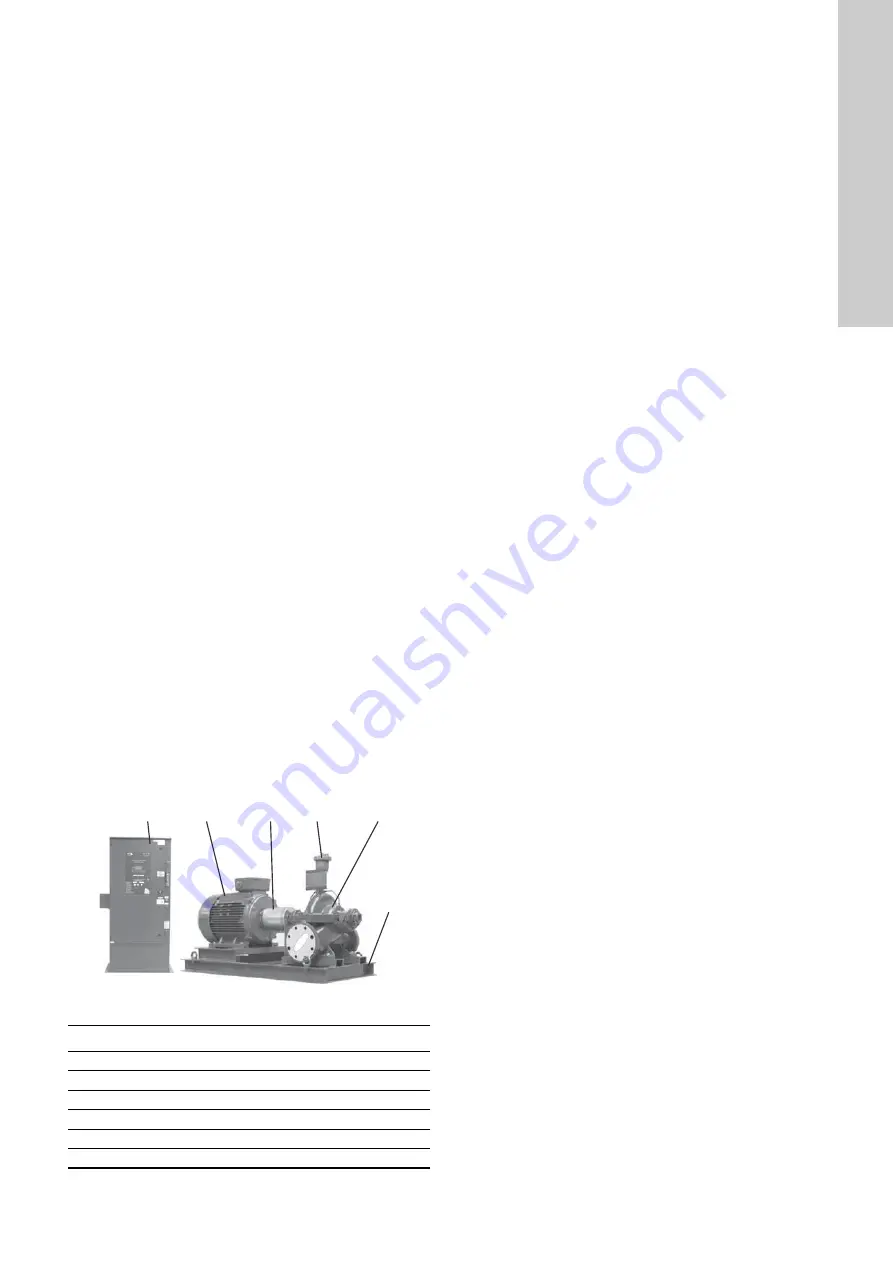

4. Product description

4.1 Fire pump set

The fire pump set consists of a pump, an electric motor and a

controller. Pump and motor are connected via a flexible coupling.

All components are adapted to each other and mounted on a

common base frame ready for installation. The base frame is

made of steel channel. The controller can also placed separately.

The fire pump set comes ready for operation.

As an example, the most important components of the fire pump

set are shown in fig. 2. It shows an HSEF fire pump set with a

Grundfos horizontal split case pump and an electric motor, type

MMG. Pump and motor are connected by a flexible coupling.

The controller is installed separately.

Fig. 2

Example of fire pump set

4.2 Pump

The fire pump set comes with a Grundfos HSEF horizontal split

case pump or a Grundfos DNF end-suction pump. The pumps are

FM-approved and UL-listed.

The impeller diameter of both pumps can be reduced to

customise the pump performance to a certain duty point.

The actual impeller diameter may therefore deviate from the

standard diameters stated in catalogues, data sheets etc.

The actual impeller diameter is stated on the pump nameplate.

4.2.1 Split case pump

The Grundfos HSEF horizontal split case pump is a non-self-

priming, single-stage pump. It has inline axial suction and

discharge ports with PN 10 or PN 16 ANSI flanges. An adapter

flange from ANSI to DIN is available and must be ordered

separately. The pumps are equipped with a stuffing box, type

SNEA or SNFA (see section

6.1.3 Type key for stuffing box

), and

with an automatic air release valve making venting unnecessary.

4.2.2 End-suction pump

The pumps are non-self-priming, single-stage Grundfos DNF

standard pumps with spiral housing. The pumps have an axial

suction port and a radial discharge port with PN 10 or PN 16 DIN

flanges.

The DNF pump is equipped with a stuffing box, type SNEA or

SNFA. See section

6.1.3 Type key for stuffing box

4.3 Motor

The pumps are driven by a 2- or 4-pole Grundfos MMG-E motor

(15-315 kW) or a Siemens motor (355 kW). All motors are

produced according to IEC 60034. The rated motor power is

adapted to the power requirement of the pump. The combinations

of motors and pumps are shown in section

.

4.4 Controller

4.4.1 General description

The fire pump set is controlled via a Tornatech controller

especially sized for electric motors driving fire pumps.

The controller starts the pump automatically and monitors the

motor. It is FM-approved.

As soon as the sprinklers are activated due to an alarm and water

is consumed, the pressure in the discharge pipe will be reduced.

If the pressure becomes lower than the cut-in pressure set on the

control panel, the pump will start automatically.

Normally, the pump is stopped manually via the controller.

But automatic stop is also possible if all starting causes have

returned to normal.

For test run and set-up, manual operation is possible.

The individual controller models differ mainly by starting method

and power range.

Starting method, model GPA

This model is used where the electricity works or the capacity of

the power source permits direct-on-line starting.

Full voltage is applied to the motor as soon as the controller

receives a start command.

Starting method, model GPY

When the controller receives a start command, the motor is

connected in star. After a time delay, it changes over to delta

connection with full voltage to the motor windings. This controller

is of the open transition type. The motor is disconnected from the

mains during the transition from start (star) to run (delta) mode.

TM

04 51

64 270

9

Pos.

Component

1

Base frame

2

Controller

3

Pump

4

Automatic air release valve

5

Motor

6

Coupling with coupling guard

2

5

6

4

3

1