Model T32304 (Mfd. Since 02/21)

-39-

Symptom

Possible Cause

Possible Solution

Machine has

vibration or noisy

operation.

1. Motor or component loose.

2. Stand feet not adjusted properly.

3. Blade weld at fault/teeth broken.

4. V-belt worn, loose, pulleys misaligned or

belt slapping cover.

5. Pulley loose.

6. Motor mount loose/broken.

7. Motor fan rubbing on fan cover.

8. Centrifugal switch.

9. Motor bearings at fault.

1. Replace damaged or missing bolts/nuts or tighten if

loose.

2. Adjust stand feet to stabilize machine.

3. Replace blade (

Page 29).

4. Inspect/replace belt (

Page 41). Realign pulleys if

necessary.

5. Secure pulley on shaft.

6. Tighten/replace.

7. Fix/replace fan cover; replace loose/damaged fan.

8. Replace.

9. Test by rotating shaft; rotational grinding/loose shaft

requires bearing replacement.

Motor & Electrical (Cont.)

Symptom

Possible Cause

Possible Solution

Blade or teeth

break/crack.

1. Blade tension is incorrect.

2. Blade is incorrect for application.

3. Excessive feed rate/pressure.

4. Blade is dull/weld at end-of-life.

5. Blade tracking is incorrect.

6. Blade guides/support bearings improperly

adjusted.

7. Bone stuck in blade guides/support

bearings.

1. Adjust blade tension (

Page 25).

2. Use correct blade for application.

3. Reduce feed rate/pressure.

4. Replace blade (

Page 29).

5. Adjust blade tracking (

Page 21).

6. Adjust blade guides/support bearings (

Page 27).

Replace if faulty.

7. Clean and sanitize blade guides/support bearings

(

Page 33).

Blade tracks

incorrectly or comes

off wheels.

1. Blade tracking is incorrect.

2. Blade tension too loose.

3. Blade guides/support bearings improperly

adjusted.

4. Excessive feed rate/pressure.

5. Incorrect blade for machine.

6. Blade is bell-mouthed, worn, or dull.

1. Adjust blade tracking (

Page 21).

2. Increase blade tension (

Page 25).

3. Adjust blade guides/support bearings (

Page 27).

4. Reduce feed rate/pressure.

5. Install correct blade (

Page 29).

6. Replace blade (

Page 29). Remove tension from

blade when not in use.

Cut is crooked or

blade wanders

(blade lead).

1. Excessive feed rate/pressure.

2. Blade tension too loose.

3. Blade is too narrow or tooth type/TPI is

incorrect for operation.

4. Blade guides/support bearings improperly

adjusted.

5. Blade dull or has damaged tooth set.

6. Blade tracking is incorrect.

1. Reduce feed rate/pressure.

2. Increase blade tension (

Page 25).

3. Use wider blade. Ensure tooth type & TPI are

correct.

4. Adjust blade guides/support bearings (

Page 27).

5. Replace blade (

Page 29).

6. Adjust blade tracking (

Page 21).

Blade dulls

prematurely.

1. Excessive feed rate/pressure.

2. Incorrect blade tooth type or TPI.

3. Blade is twisted.

4. Blade is slipping on wheel.

5. Blade guides hitting teeth and damaging

tooth set.

1. Reduce feed rate/pressure.

2. Use blade with correct tooth type and TPI.

3. Adjust/replace blade (

Page 29).

4. Adjust blade tension (

Page 25).

5. Adjust blade guides/support bearings (

Page 27).

Operations

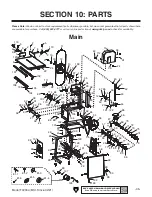

Summary of Contents for T32304

Page 52: ......