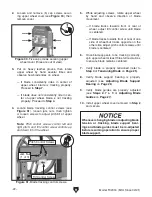

To prevent blade falling off wheels and

causing injury or property damage, DO NOT

rotate blade tension nut when saw is oper-

ating. ALWAYS disconnect machine from

power before adjusting blade tension.

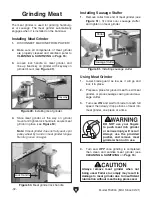

Saw blades are very sharp

and can quickly cause cut-

ting injuries. Always wear

heavy-leather gloves when

handling saw blades.

Figure 32. Location of blade guard and blade

guide assembly components.

Model T32304 (Mfd. Since 02/21)

-25-

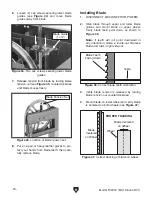

Tensioning Blade

A properly tensioned blade is essential for making

accurate cuts, maximizing blade life, and making

other bandsaw adjustments. However, a properly

tensioned blade will not compensate for cutting

problems caused by excessive feed rate, hard-

ness variations between meats and bones, and

improper blade selection.

Optimal cutting results for any type of workpiece

are achieved through a combination of correct

blade selection, proper blade tension, properly

adjusted blade guides and other bandsaw compo-

nents, and using an appropriate feed rate.

Improper blade tension is unsafe, produces inac-

curate and inconsistent results, and introduces

unnecessary wear on bandsaw components.

Over-tensioning the blade increases the chance

of the blade breaking or wheel misalignment.

Under-tensioned blades wander excessively while

cutting.

Adjusting Blade

Guard

The blade guard protects the operator from acci-

dental contact with the portion of the blade that is

not cutting through a workpiece.

The blade guide lock knob (see

Figure 32) on the

guide rail allows you to raise and lower the blade

guard and blade guide assembly. To remove the

blade guard, loosen and remove (2) cap screws

securing the blade guard to the blade guide

assembly (see

Figure 32).

IMPORTANT: Keep the blade guide assembly

within an inch of the material you are cutting. This

will provide adequate support for the blade where

the pressure is greatest. This adjustment is crucial

when cutting through bone!

Cap Screw

(1 of 2)

Blade Guard

Blade

Guide

Lock

Knob

Guide

Rail

Summary of Contents for T32304

Page 52: ......