Whenever changing blade or adjusting blade

tension or tracking, blade support bear-

ings and blade guides must be re-adjusted

before resuming operation to ensure proper

blade support.

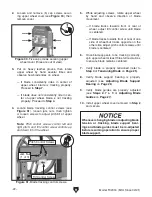

Figure 30. Five cap screws securing upper

wheel cover (three are out of view).

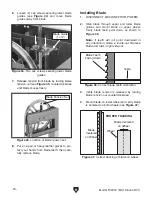

Figure 31. Blade tracking control screws.

-22-

Model T32304 (Mfd. Since 02/21)

2. Loosen and remove (5) cap screws secur-

ing upper wheel cover (see

Figure 30), then

remove cover.

3. Put on heavy leather gloves, then rotate

upper wheel by hand several times and

observe how blade rides on wheel.

— If blade consistently rides in center of

upper wheel, blade is tracking properly.

Proceed to

Step 7.

— If blade does not consistently ride in cen-

ter of upper wheel, blade is not tracking

properly. Proceed to

Step 4.

4. Locate blade tracking control screws (see

Figure 31), loosen jam nuts, then tighten

or loosen screws to adjust pitch/tilt of upper

wheel.

Note: Pitch control screws control left and

right pitch, and tilt control screw controls up

and down tilt of the wheel.

5. While adjusting screws, rotate upper wheel

by hand and observe direction of blade

movement.

— If blade tracks towards front or rear of

wheel, adjust tilt control screw until blade

is centered.

— If blade tracks towards front or rear of one

side of wheel but tracks opposite on the

other side, adjust pitch control screws until

blade is centered.

6. Once blade appears to be tracking correctly,

spin upper wheel at least three full revolutions

to ensure blade remains centered.

7. Verify blade is properly tensioned (refer to

Step 4 of Tensioning Blade on Page 25).

8. Verify blade support bearing is properly

adjusted (see

Adjusting Blade Support

Bearing on Page 26).

9. Verify blade guides are properly adjusted

(see

Steps 2–7 & 9 of Adjusting Blade

Guides on Page 27).

10. Install upper wheel cover removed in Step 2

and secure.

Tilt Control Screw

Pitch Control Screws

Jam Nut

(1 of 3)

Summary of Contents for T32304

Page 52: ......