Model T32002 (Mfd. Since 02/20)

-25-

The rotary shaft included with the T32002 allows

for grinding and polishing in tight spaces with

greater control. DO NOT operate the rotary shaft

with sharp bends.

Operating

Rotary Shaft

1.

DISCONNECT MACHINE FROM POWER!

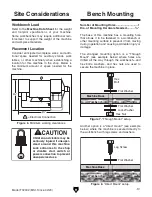

2. Insert square-shaped flexible rotating shaft

inside shaft hose into square hole in grinding

wheel standoff stud (see

Figure 16).

Installing Rotating Shaft

Figure 17. Rotating shaft attached to grinder.

Wheel Cover

Plastic Nut

3. Use plastic nut on rotary shaft to secure

rotary shaft to wheel cover (see

Figure 17).

Figure 16. Flexible rotating shaft inserted into

standoff stud (wheel guard removed for clarity).

Flexible Rotating Shaft

Standoff Stud

Rotary Shaft

The Model T32002 comes with a grinding bit and

uses bits and cutters with a

1

⁄

8

" diameter shaft.

See the Grizzly catalog or website for a complete

listing of available bits and accessories.

Installing Bits

To install a bit:

1. DISCONNECT MACHINE FROM POWER!

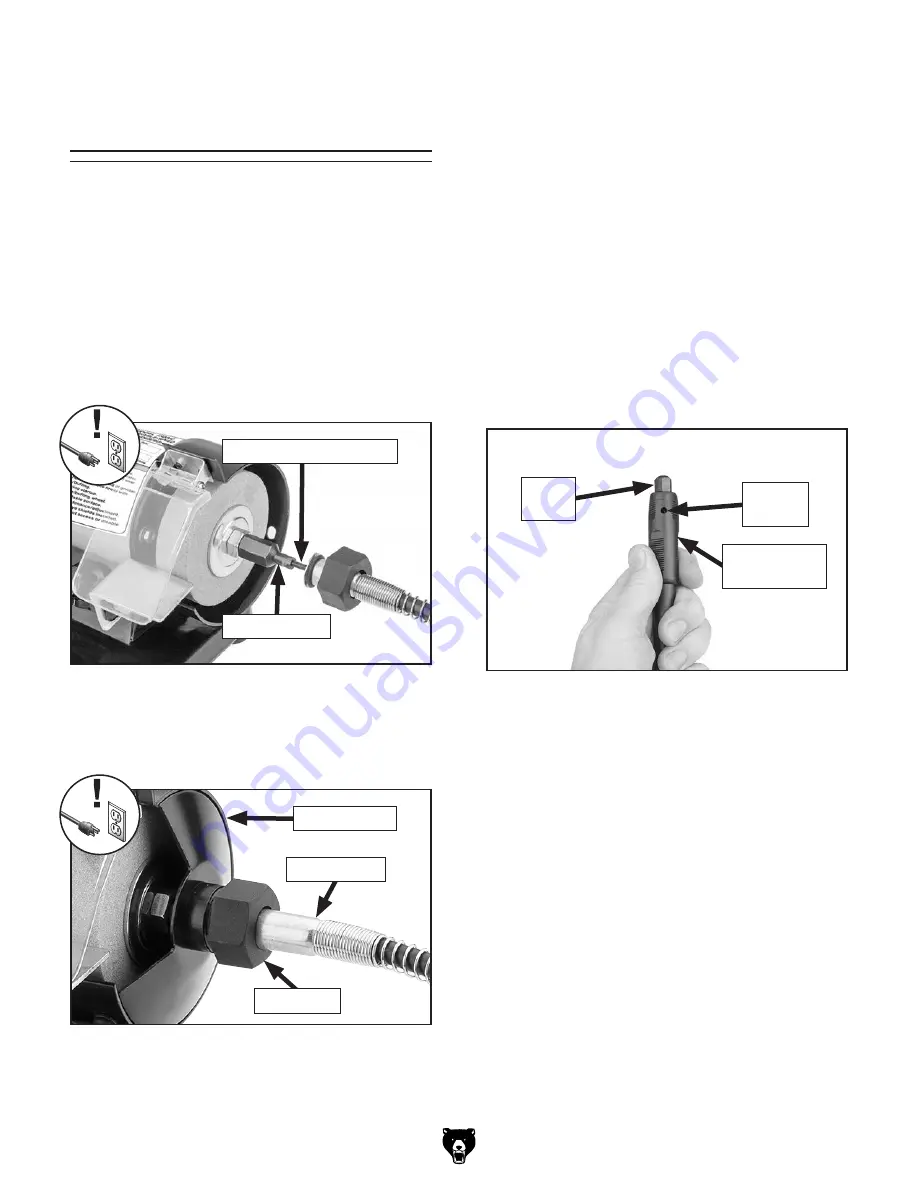

2. Rotate collet nut until locking holes in rotary

shaft grip align (see

Figure 18), then insert

pin wrench.

Figure 18. Location of locking holes in rotary

shaft grip.

Collet

Nut

Rotary Shaft

Grip

Locking

Hole

3. Loosen collet nut by turning counterclock-

wise.

Note: DO NOT completely remove collet nut

from shaft.

4. Insert bit shank into collet.

Note: At least

1

⁄

2

" of bit shank should be

mounted into end of collet.

Items Needed

Qty

Pin Wrench ........................................................ 1

Open-End Wrench 9mm.................................... 1

Summary of Contents for T32002

Page 36: ......