-22-

Model T32002 (Mfd. Since 02/20)

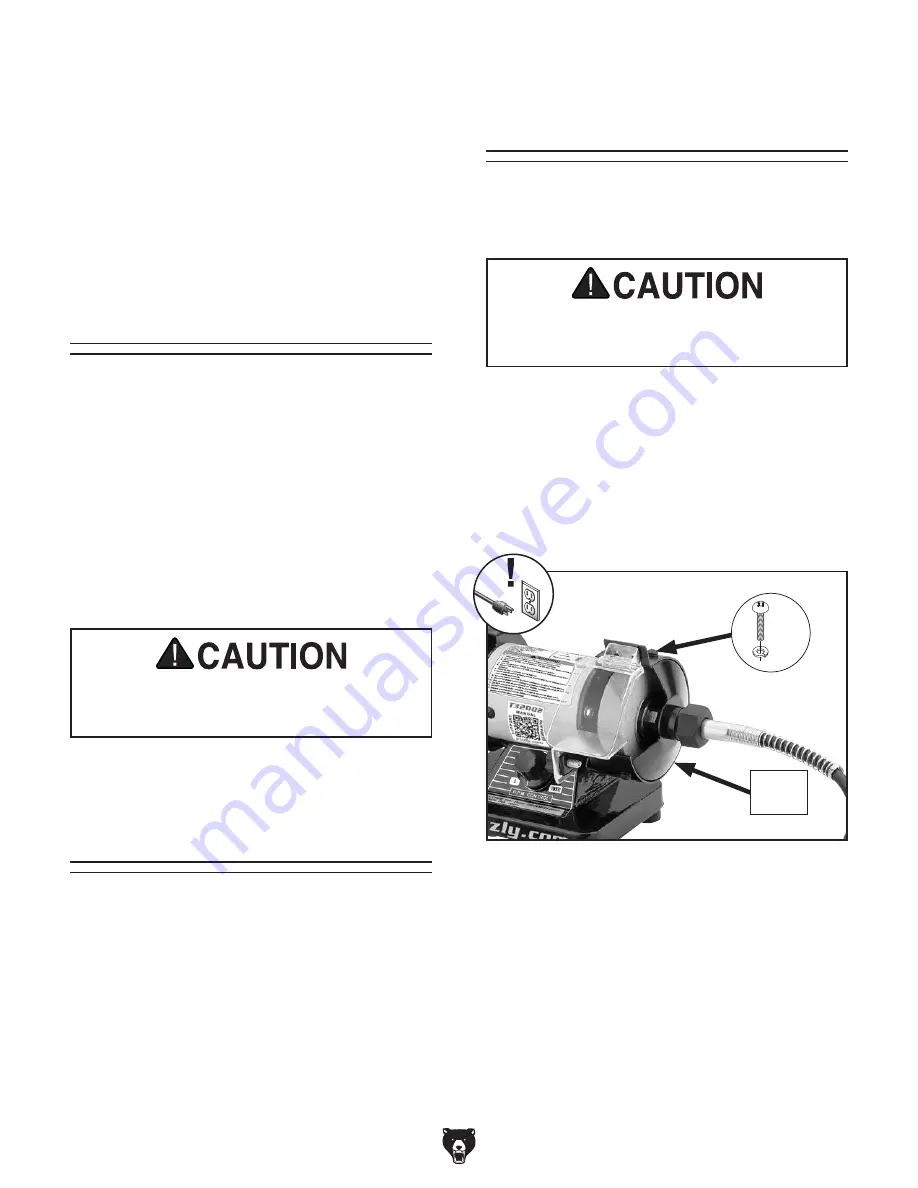

ALWAYS visually inspect and perform a

“ring test” on a wheel before installing. DO

NOT use damaged wheels!

Installing/Removing

Grinding Wheel

To install/remove grinding wheel:

1. DISCONNECT MACHINE FROM POWER!

2. Remove outer grinding wheel guard by loos-

ening (3) M5-.8 x 5 Phillips head screws with

(3) lock washers holding wheel guard in place

(see

Figure 12).

Figure 12. Fasteners securing wheel guard.

Wheel

Guard

x 3

— An undamaged grinding wheel will emit a

clear metallic ring or “ping” sound in each

of these spots. A damaged grinding wheel

will respond with a dull thud that has no

clear tone.

— If you determine from ring test that grind-

ing wheel is damaged, DO NOT use it!

Dressing

Grinding Wheel

Depending on the type of grinding you do, the

grinding wheel may require periodic dressing.

There are several different types of wheel dressing

devices available on the market (see

Accessories

on

Page 27 for examples). Dressing restores the

abrasive quality of the wheel surface and brings

the wheel edge back to a square form.

Refer to the instructions that accompany your

dressing accessory for complete details on how

to properly dress the wheel.

Always adjust tool rest after dressing or

replacing grinding wheel. Failure to do so

could lead to workpiece kickback and injury.

Wheels with varying grit are useful for different

operations and workpiece materials. DO NOT

leave wheel mounted when machine is not in use.

Grinding wheels can be easily damaged, so it is

important to store them properly. Follow all wheel

manufacturer storage instructions. Always store

grinding wheels in a location that is dry and pro-

tected from potential damage due to them being

dropped or having other items dropped on them.

Also, avoid storing grinding wheels where there is

high humidity, extreme heat or cold, or solvents.

Storing

Grinding Wheel

Summary of Contents for T32002

Page 36: ......