Model T32002 (Mfd. Since 02/20)

-11-

Additional Safety for Grinders

Serious injury or death can occur from impact injuries if grinding wheel breaks apart during use.

Entanglement/amputation injuries can occur from being caught in moving parts or in-running

pinch points. Flying sparks can ignite explosive or flammable materials. Rotating grinding

wheels can easily remove skin. To minimize risk of getting hurt or killed, anyone operating

machine MUST completely heed hazards and warnings below.

STARTING GRINDER. If a wheel is damaged,

it will usually fly apart shortly after start-up. To

protect yourself, always stand to side of grinder

when turning it

ON and allow it to run for at least

one minute before standing in front of it.

VISUAL INSPECTION. Verify that grinding wheels

are free of cracks, chips, or dents in wheel surface

before installing. Do not use wheel if it has any

of these problems or it could break apart during

operation.

VIBRATING WHEEL. Never use a wheel that

vibrates. Replace wheel or shaft bearings

immediately.

WHEEL SPEED RATING. Wheels operated at a

faster speed than rated for may break apart dur-

ing operation. Before mounting a new wheel, be

sure wheel RPM rating is equal to or higher than

speed of grinder. Never use unmarked wheels or

wheel rated for a lower speed than grinder.

AVOIDING ENTANGLEMENT. Becoming entan-

gled in moving parts can cause severe injury or

death. Keep all guards and covers in place; DO

NOT wear loose clothing, gloves, or jewelry; and

tie back long hair.

SIDE & TOP GRINDING. Grinding on side of

wheels can cause them to crack and burst—unless

wheel is rated for side grinding. Grinding on top of

wheels greatly increases risk of workpiece kick-

back. Always grind on downward part of wheel.

WHEEL ATTACHMENT. Only use flanges includ-

ed with grinder when mounting wheels. Other

flanges may not properly secure wheel and cause

an accident. Do not use warped or damaged

flanges. Only tighten wheel spindle nut enough to

drive wheel and prevent slippage.

TOOL REST POSITION. If tool rest is too far

away from wheel, it forms a gap called an "in-

running nip point" which may cause workpiece to

be pulled down, leading to loss of control and pull-

ing your hand into grinding wheel. Keep tool rest

within

1

⁄

8

" from wheel when operating to minimize

risk of pinching and crushing injuries. Replace

grinding wheel when tool rest gap is wider than

1

⁄

8

", and when no additional adjustment can be

made.

HAND & WHEEL CONTACT. Keep a firm grip

on workpiece and position your hands a safe

distance away when grinding. Anticipate when

workpiece will heat up, and cool it before it

becomes too hot to hold, or use an appropriate

clamp. Avoid wearing gloves as they may get

caught in grinding wheel and cause even more

serious entanglement injuries.

RING TEST. Perform a "ring test" on grinding

wheels before installation to ensure they are safe

to use. A wheel that does NOT pass ring test may

break or fly apart during operation.

EYE SHIELDS. Place eye shields close to grind-

ing wheel and re-adjust as wheel wears down.

EYE, FACE, & LUNG PROTECTION. Grinding

ejects small particles at a high rate of speed.

These particles can cause blindness, skin injuries

or respiratory damage. ALWAYS wear approved

clothing, safety goggles, face shield, and a respi-

rator for type of grinding to be done.

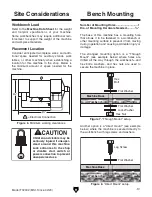

SAFE MOUNTING & WORK AREA. An unse-

cured grinder may become dangerously out of

control during operation. Before use, verify grinder

is FIRMLY secured in a location free of explosive

or flammable materials. Frequently clean grinding

dust from beneath grinder and inside wheel cover.

Summary of Contents for T32002

Page 36: ......