Model T27710 (Mfd. Since 04/16)

-25-

Removing

Stuck Logs

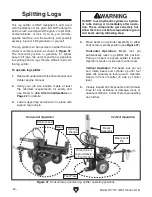

6. Put on safety glasses, hearing protection,

and thick leather gloves.

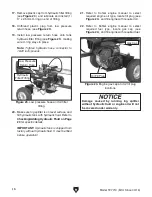

7. Start engine and place log lengthwise on

beam and flat against foot plate, as shown in

Figure 38.

8. Make sure bystanders are out of work zone

and that zone is clear of split logs. The work

zone is an approximate 6-foot sphere that

extends around log splitter, as shown in

Figure 37.

9. While keeping hands clear of splitting wedge,

use control lever to split log, retract wedge,

and remove split log from work zone.

Foot Plate

Beam

Log

Figure 38. Best placement of log against beam

and foot plate (horizontal operation shown).

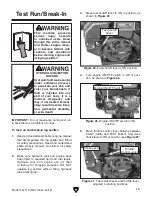

Never use your hands to remove a log stuck

on wedge, as it could crush hands and fin-

gers during accidental startup. Always use

log dislodger to remove log. If log is still

stuck, turn log splitter OFF and use sledge

hammer and crow bar to remove stuck log.

This log splitter features a dislodger for helping

eject partially split logs or logs that get stuck on

the wedge. To eject a stuck log, move the control

lever to reverse until the split log contacts the dis-

lodger brackets shown in

Figure 39 and slips off

the wedge.

Figure 39. Dislodger location.

If the log remains stuck on the wedge, turn the

log splitter

OFF and use a sledge hammer and

crowbar to remove the log.

Wedge

Dislodger

Summary of Contents for T27710

Page 40: ...38 Model T27710 Mfd Since 04 16...

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......

Page 48: ......

Page 49: ......

Page 50: ......

Page 51: ......

Page 52: ......

Page 53: ......

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......

Page 58: ......

Page 59: ......

Page 60: ......

Page 61: ......

Page 62: ......

Page 115: ...53 18 690 01 Rev C KohlerEngines com...

Page 116: ...54 KohlerEngines com 18 690 01 Rev C...

Page 117: ...55 18 690 01 Rev C KohlerEngines com...

Page 118: ...56 KohlerEngines com 18 690 01 Rev C 2015 by Kohler Co All rights reserved...