45

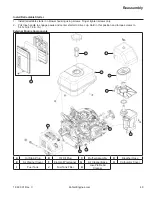

Reassembly

18 690 01 Rev. C

KohlerEngines.com

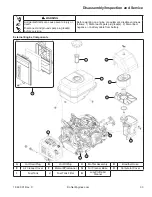

Install Closure Plate

Torque Sequence

5

2

4

6

1

3

NOTE: Make sure governor lever is against cup on

governor gear assembly.

1. Check to be sure sealing surfaces of crankcase and

closure plate are clean and free of nicks or burrs.

2. Install dowel pins and install a new closure plate

gasket (dry) onto dowel pins.

3. Install closure plate to crankcase. Carefully seat

ends of camshaft and balance shaft into their mating

bearings. Rotate crankshaft slightly to help engage

governor gear teeth.

4. Install screws securing closure plate to crankcase.

Torque screws in sequence shown to 24 N·m

(212 in. lb.).

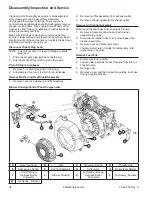

Flywheel/Ignition Components

A

B

C

D

F

E

A

Flywheel Retaining

Nut

B

Drive Cup

C

Flywheel Fan

D

Flywheel

E

Flywheel Shield

F

Ignition Module

Install Flywheel

CAUTION

Damaging Crankshaft and Flywheel can

cause personal injury.

Using improper procedures can lead to broken

fragments. Broken fragments could be thrown from

engine. Always observe and use precautions and

procedures when installing

fl

ywheel.

NOTE: Before installing

fl

ywheel make sure crankshaft

taper and

fl

ywheel hub bore are clean, dry, and

completely free of lubricants. Presence of

lubricants can cause

fl

ywheel to be over

stressed and damaged when nut is torqued to

speci

fi

cation.

NOTE: Make sure

fl

ywheel key is installed properly in

keyway. Flywheel can become cracked or

damaged if key is not installed properly.

1. Install woodruff key into keyway of crankshaft. Be

sure that key is properly seated and parallel with

taper of shaft.

2. Install

fl

ywheel onto crankshaft, being careful not to

shift position of woodruff key.

3. Install

fl

ywheel shield and secure with screw.

4. Install fan bosses into matching holes in

fl

ywheel.

5. Position drive cup on

fl

ywheel, engaging boss on its

base with corresponding hole on

fl

ywheel. Hold in

position and install nut. Finger tighten to keep cup

indexed.

6. Use

a

fl

ywheel strap wrench and torque wrench to

tighten

fl

ywheel nut. Torque nut to 74 N·m

(655 in. lb.).

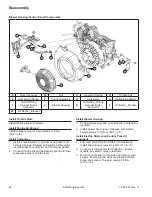

Install Ignition Module

NOTE: Ensure ignition module is correctly oriented.

1. Turn

fl

ywheel so magnet is away from location

where ignition module will be installed.

2. Install ignition module loosely to bosses with screws.

Move module as far away from

fl

ywheel as possible,

then tighten screws just enough to hold it in position.

3. Rotate

fl

ywheel in a clockwise direction until magnet

is under 1 leg of ignition module.

4. Insert a 0.254 mm (0.010 in.)

fl

at feeler gauge

between leg of module and magnet. Loosen nearest

screw, allowing magnet to draw module against

feeler gauge. Push against module to hold leg tight

against feeler gauge while tightening screw.

5. Rotate

fl

ywheel until magnet is under other leg of

module. Loosen nearest screw, allowing magnet to

draw module against feeler gauge. Push against

module to hold leg tight against feeler gauge while

tightening screw.

6. Torque both module screws to 8 N·m (70.8 in. lb.).

7. Rotate

fl

ywheel back and forth, checking to make

sure magnet does not strike module.

Summary of Contents for T27710

Page 40: ...38 Model T27710 Mfd Since 04 16...

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......

Page 48: ......

Page 49: ......

Page 50: ......

Page 51: ......

Page 52: ......

Page 53: ......

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......

Page 58: ......

Page 59: ......

Page 60: ......

Page 61: ......

Page 62: ......

Page 115: ...53 18 690 01 Rev C KohlerEngines com...

Page 116: ...54 KohlerEngines com 18 690 01 Rev C...

Page 117: ...55 18 690 01 Rev C KohlerEngines com...

Page 118: ...56 KohlerEngines com 18 690 01 Rev C 2015 by Kohler Co All rights reserved...