-30-

Model G0901 (Mfd. Since 09/19)

Quarter Sawing

Quarter sawing is any method of milling a log

that produces primarily quartersawn lumber. In

general, this produces a mixture of quartersawn

and riftsawn lumber. Producing only quartersawn

lumber can be time-consuming and leaves a lot

of scrap.

The method below is relatively simple and pro-

duces quartersawn and riftsawn lumber. Many

other methods exist—all with unique benefits and

downsides. A sawyer should choose a method

based on the log used, lumber needed, and per-

sonal preference.

To quarter-saw a log:

1. Inspect log and outline a sawing plan.

Consider orientation of log on track and

where to start cutting to produce the best

lumber. Mark planned cuts on end of log.

2. Load log to track bed and secure with log

supports and log clamp.

3. Cut a thick slab and remove it from log (see

Figure 40). Set slab aside for now.

4. Rotate log 180° and secure it. Cut a slab about

the same size as the first one (see

Figure

40). To reduce waste, make sure the distance

between cuts—the height of the resulting

cant—is divisible by the thickness of lumber to

be produced. Set slab aside for now.

Thick

Slab

Cant

Thick

Slab

Log

Support

Log

Clamp

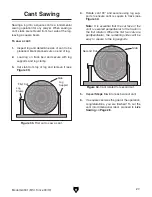

Figure 40. Thick slabs to be removed from log.

5. Rotate cant 90° and clamp to track bed, using

log supports to ensure cant is perpendicular

to track (see

Figure 41). Take care that log

clamp holds cant tight against supports.

6. Cut a thin slab and remove it from cant (see

Figure 41). Discard slab.

Thin

Slab

Cant

Figure 41. Thin slab to be removed from cant.

7. Rotate cant 180° and secure it.

8. Cut a thin slab and remove it from cant (see

Figure 42). Discard slab.

9. Cut above pith, then remove top cant from

the cant secured to the track (see

Figure 42).

Set top cant aside for now.

10. Cut below pith. To reduce waste, cut a board

that is a usable thickness when cutting below

pith. Remove board with pith from cant (see

Figure 42). Set board aside for now.

Thin

Slab

Pith

Cant

Cant

Figure 42. Two rectangular cants and pith to be

removed.

Summary of Contents for G0901

Page 56: ......