-16-

Model G0901 (Mfd. Since 09/19)

Assembly

4. Use forklift or hoist to lift carriage from pal-

let and move it out of the way during track

assembly.

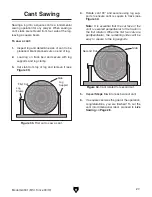

5. If workspace is uneven or on soft ground,

place boards down to support adjustable feet

and distribute weight of machine.

6. With the help of an assistant, remove both

track sections and place them in assembly

location, oriented as shown in

Figure 11.

To assemble sawmill:

1. Remove top and sides from crate.

2. Unbolt carriage from crate pallet.

3. Remove (6) M10-1.5 x 20 hex bolts, 10mm

lock washers, and 10mm flat washers from

carriage, then attach lift bar to carriage with

removed hardware (see

Figure 10).

The machine must be fully assembled before it

can be operated. Before beginning the assembly

process, refer to

Needed for Setup and gather

all listed items. To ensure the assembly process

goes smoothly, first clean any parts that are cov-

ered or coated in heavy-duty rust preventative (if

applicable).

Front

Track

Rails

Figure 11. Track section orientation.

HEAVY LIFT!

Straining or crushing injury

may occur from improperly

lifting machine or some of

its parts. To reduce this risk,

get help from other people

and use a forklift (or other

lifting equipment) rated for

weight of this machine.

Figure 10. Lift bar installed on carriage.

Lift Bar

x 6

Summary of Contents for G0901

Page 56: ......