Model G0745 (Mfg. Since 11/13)

-27-

Aligning Cutting Tool with Spindle

Centerline

For most operations, the cutting tool tip should be

aligned with the spindle centerline, as illustrated

in

figure 29.

Cutting

Tool

Spindle

Center

Line

figure 29. Cutting tool aligned with spindle

centerline (viewed from tailstock).

there are a number of ways to check and align

the cutting tool to the spindle centerline. if nec-

essary, you can raise the cutting tool by placing

steel shims underneath it. the shims should be

as long and as wide as the cutting tool to properly

support it.

below are two common methods:

•

Move the tailstock center over the cross slide

and use a fine ruler to measure the distance

from the surface of the cross slide to the tip

of the center. adjust the cutting tool height so

it is the same distance above the cross slide

as the tailstock center.

•

align the tip of the cutting tool with a tailstock

center, as instructed in the following proce-

dure.

To align the cutting tool with the tailstock

center:

1. Mount the cutting tool in the tool post, then

secure the post so the tool faces the tailstock.

2. install a center in the tailstock, and position

the center tip near the cutting tool tip.

3. lock the tailstock and quill in place.

4. adjust the height of the cutting tool so that the

tool tip is aligned vertically with the center tip,

as illustrated below.

figure 30. Cutting tool aligned to the tailstock

center.

Cutting

Tool

Tailstock

Center

(Side View)

Cutting

Tool

Tailstock

Center

(Top View)

Tools Needed

Qty

hex Wrench 5mm .............................................. 1

steel shims ....................................... as Needed

Cutting tool ....................................................... 1

tailstock Center ................................................. 1

Summary of Contents for G0745

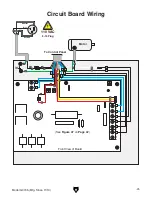

Page 44: ... 42 Model G0745 Mfg Since 11 13 Figure 47 Circuit board ...

Page 52: ......