Model G0745 (Mfg. Since 11/13)

-23-

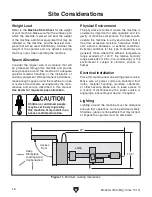

Insufficient

Jaw Clamping

Unstable

Workpiece

Bar Stock

Cylinder

Unsafe Jaw Position

Poor Scroll

Gear Engagement

Safer Inside

Jaw Use

Unsafe Inside

Jaw Use

Unsafe Jaw

Position

Safer Outside

Jaw Use

Poor Scroll Gear Engagement

Unsafe Jaw Position and

Poor Scroll

Gear

Engagement

Poor Grip

Unstable

Workpiece

Shallow

Bar Stock

Shallow

Bar Stock

Safer Outside

Jaw Use

Safer Inside

Jaw Use

CORRECT

CORRECT

CORRECT

CORRECT

INCORRECT

INCORRECT

INCORRECT

INCORRECT

Scroll Chuck

Clamping

figure 22. Jaw selection and workpiece holding.

this 3-jaw scroll-type chuck has an internal scroll-

gear that moves all jaws in unison when adjusted

with the chuck key. this chuck holds cylindrical

parts on-center with the axis of spindle rotation

and can be rotated at high speeds if the workpiece

is properly clamped and balanced.

Never mix jaw types or positions to

accommodate an odd-shaped workpiece. the

chuck will spin out of balance and may throw the

workpiece! instead, use an independent jaw chuck

or a faceplate (not included).

6. insert jaw #1 into the same jaw guide.

7. rotate outer ring so tip of scroll-gear lead

thread engages jaw. pull the jaw; it should be

locked into the jaw guide.

8. install remaining jaws in numerical order in

the same manner, starting to the right of the

jaw you just installed. the jaws should con-

verge evenly at the center of the chuck when

properly installed.

Tip: To ensure smooth installation, make

sure the jaws are straight up and down and

do not bind in the scroll gear.

— if the jaws do not converge evenly, remove

them. re-install the jaws sequentially 1–3,

and make sure each one engages with the

scroll-gear lead thread during its first rota-

tion.

5. rotate outer ring until tip of scroll-gear lead

thread begins to enter a jaw guide (see

figure 21).

Scroll Gear

Lead Thread

1

figure 21. lead thread entering jaw guide.

Summary of Contents for G0745

Page 44: ... 42 Model G0745 Mfg Since 11 13 Figure 47 Circuit board ...

Page 52: ......