-22-

Model G0580 (Mfd. Since 11/06)

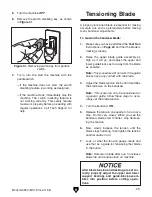

Adjusting Positive

Stop

Figure 26. Squaring table to blade.

5. Adjust the positive stop bolt to the adjusted

height of the table and tighten the jam nut.

6. Rest the table on the positive stop bolt and

check for accuracy.

Note: See Calibrating Table Tilt Scale on

Page 28.

The positive stop allows the table to be reset 90˚

to the blade after tilting to the right.

Tools

Needed: Qty

Wrenches 13mm ............................................... 2

Machinist's Square ............................................ 1

To set the positive stop:

1. Ensure the blade is correctly tensioned as

described in

Tensioning Blade instructions

on

Page 25.

2. DISCONNECT BANDSAW FROM POWER!

3. Loosen the jam nut that locks the positive

stop adjust bolt in place.

4. Raise the guide post and place a machin-

ist’s square on the table next to the side of

the blade, as illustrated in

Figure 26. Tilt

the table until it rests 90˚ to the blade, then

secure it with the table tilt knobs.

Figure 25. Example of attached dust hose.

Dust Collection

DO NOT operate this bandsaw without an ade-

quate dust collection system. This bandsaw

creates substantial amounts of wood dust

while operating. Failure to use a dust collec-

tion system can result in short and long-term

respiratory illness.

Recommended CFM at Dust Port: 400 CFM

Do not confuse this CFM recommendation with

the rating of the dust collector. To determine the

CFM at the dust port, you must consider these

variables: (1) CFM rating of the dust collector,

(2) hose type and length between the dust col-

lector and the machine, (3) number of branches

or wyes, and (4) amount of other open lines

throughout the system. Explaining how to cal-

culate these variables is beyond the scope of

this manual. Consult an expert or purchase a

good dust collection "how-to" book.

To connect a dust collection hose:

1. Fit a 4" dust hose over the dust port, as shown

in the figure below, and secure in place with a

hose clamp.

2. Tug the hose to make sure it does not come

off.

Note: A tight fit is necessary for proper per-

formance.

Summary of Contents for G0580

Page 15: ...Model G0580 Mfd Since 11 06 13 Hardware Recognition Chart...

Page 64: ......