Model G0449/G0450 (Mfd. Since 8/13)

-47-

Tools Needed:

Qty

Phillips Head Screwdriver .................................. 1

For the scale pointer to be accurate, it must be

calibrated.

We recommend calibrating your scale pointer

any time you adjust the drum heights or table lift

screws.

To calibrate the scale pointer:

1. Sand a workpiece with the drum sander

and measure the thickness of the sanded

workpiece.

2. Loosen the screw that secures the scale

pointer, adjust it to the thickness of the

workpiece, then tighten it.

Scale Pointer

Calibration

Dust Scoops

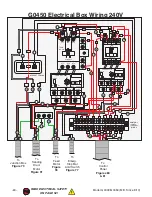

Figure 66. Location to adjust dust scoop.

Button Head

Cap Screw

Metal

Scoop

Plate

Dust Scoops

4. Adjust each scoop in this manner until the

sanding drums do not scrape the scoops,

then close the pulley cover and reinstall the

handwheel.

Figure 65. Scale pointer screw.

Tools Needed:

Qty

Hex Wrench 4, 5mm ...................................... 1ea

The dust scoops and metal scoop plates are

correctly positioned on the top cover at the fac-

tory, however these may loosen and move during

shipping. Some trial and error will be needed to

adjust the dust scoops so they do not contact the

sanding drums.

To adjust a dust scoop:

1. DISCONNECT POWER TO SANDER!

2. Remove the handwheel and open the pulley

cover.

3. Loosen the button head cap screws and

acorn nuts securing a metal scoop plate to

the top cover (

Figure 66), move the scoop

up a little, tighten the button head cap screws

and nuts, close the top cover, and rotate the

V-belt to see if the drum srapes the scoop.

Summary of Contents for G0449

Page 80: ......