-34-

Model G0449/G0450 (Mfd. Since 8/13)

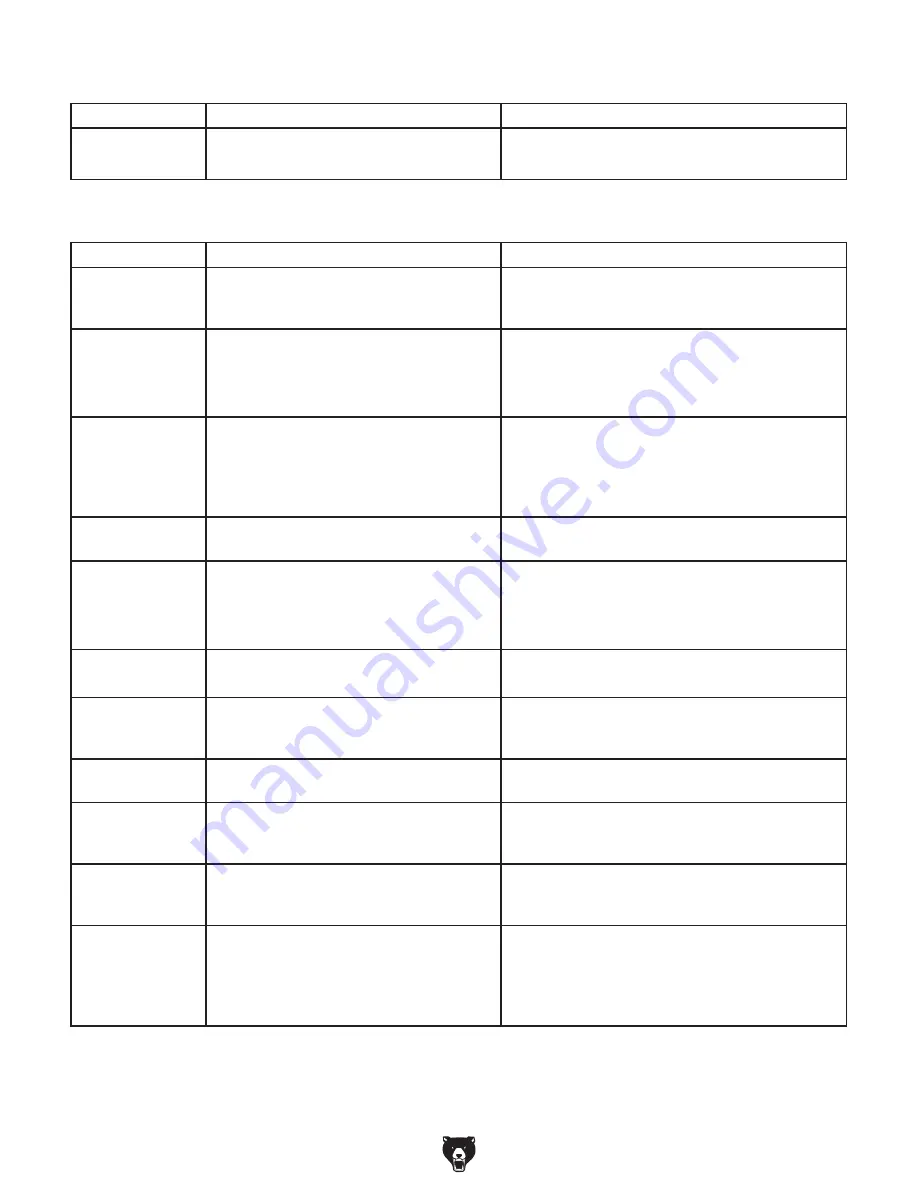

Motor & Electrical Continued

Symptom

Possible Cause

Possible Solution

Machine stalls or is

overloaded.

10. Motor is at fault.

11. Air circulation through the motor restricted.

10. Test/repair/replace.

11. Clean off motor to provide normal air circulation.

Machine Operations

Symptom

Possible Cause

Possible Solution

Drums run

backwards (G0450

only).

1. Two of the power wires are reversed

(G0450 only).

1. Switch two of the current carrying wires at the main

power block (G0450 only). (Page 20)

Machine slows

when sanding,

making squealing

noise, especially on

start-up.

1. V-belts loose.

2. V-belts worn out.

1. Tighten V-belts (Page 36).

2. Replace V-belts (Page 37).

Loud repetitious

noise coming from

machine.

1. Pulley setscrews or keys are missing or

loose.

2. Motor fan is hitting the cover.

3. V-belts are defective.

1. Inspect keys and setscrews. Replace or tighten if

necessary.

2. Adjust fan cover mounting position, tighten fan, or

shim fan cover.

3. Replace V-belts (Page 37).

Vibration when

sanding.

1. Loose drum pillow bearings.

2. Worn drum pillow bearings.

1. Tighten drum pillow bearings.

2. Replace drum pillow bearings.

Grinding,

screeching, or

rubbing noise when

sanding drums are

powered up.

1. Drum bearings lack sufficient grease.

2. Drum bearings worn.

1. Grease the pillow bearings (Page 31).

2. Replace the drum bearings.

Short V-belt

lifespan.

1. Pulleys not aligned correctly.

2. Improperly tensioned.

1. Align pulleys (Page 37).

2. Properly tension V-belts (Page 36).

Machine lacks

power; drums stop

turning under load.

1. V-belts loose.

2. Too much pressure on pressure rollers.

1. Tighten V-belts (Page 36).

2. Reduce pressure roller pressure (Page 46).

Conveyor slips

under load.

1. Conveyor is too loose.

2. Too much load.

1. Tension conveyor (Page 40).

2. Decrease load.

Conveyor tracks to

one side; conveyor

hits the roller cover.

1. Conveyor tracking is incorrect.

1. Track the conveyor so it runs straight (Page 41).

Workpiece pulls

to one side during

sanding operations.

1. One of the sanding drums is not parallel

with the table.

1. Adjust the sanding drums parallel to the table (Page

41

).

Excessive snipe.

1. Too much pressure roller pressure.

2. Too much pressure from rear pressure

rollers.

3. Lack of outfeed support.

1. Reduce pressure roller pressure (Page 46).

2. Reduce rear pressure roller pressure (Page 46).

3. Set up outfeed table or have someone catch the

workpiece as it comes out.

Summary of Contents for G0449

Page 80: ......