Page 10

G0513 Series Bandsaws

-35-

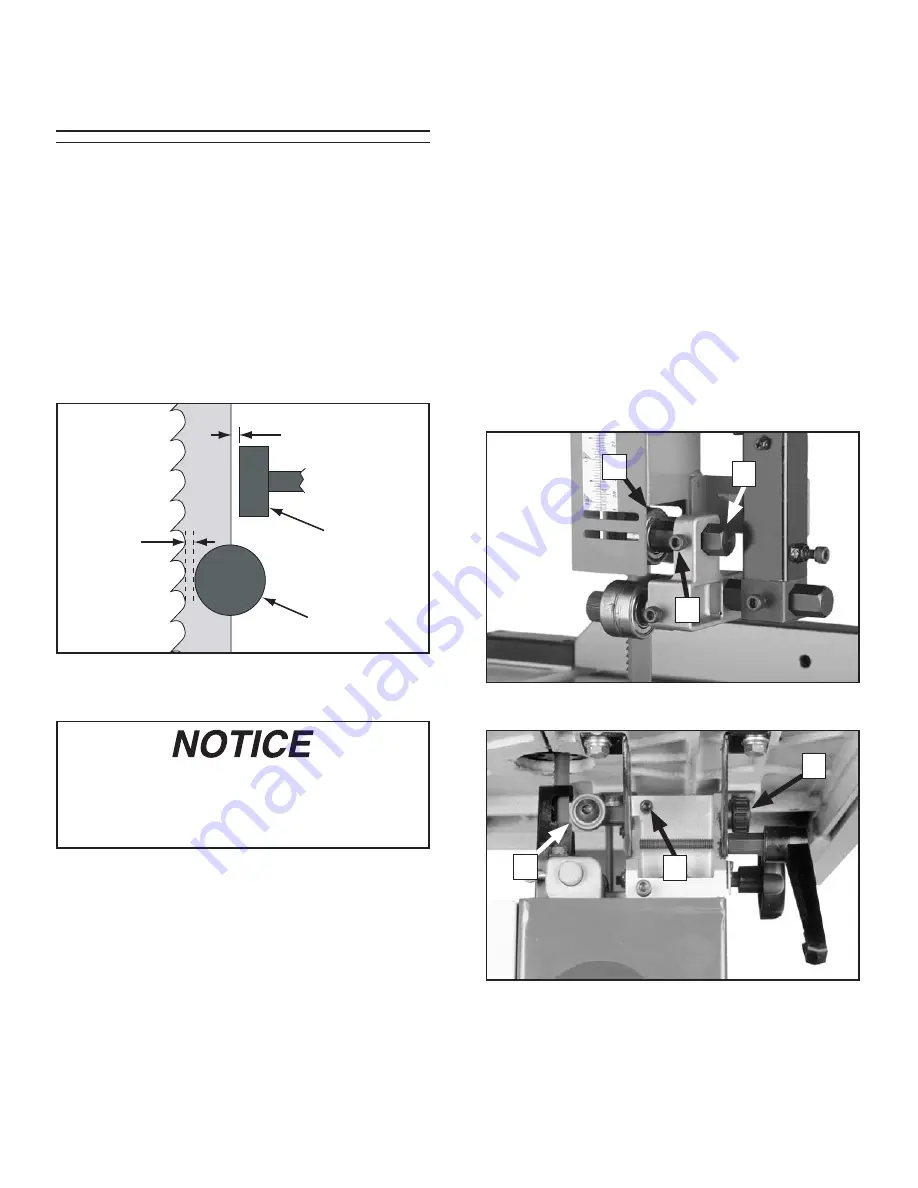

Adjusting Blade

Support Bearings

Before adjusting the blade support bear-

ings, make sure the blade is tracking prop-

erly (

Page 28

) and that it is correctly ten-

sioned (

Page 33

).

Support bearings stop excessive backward deflec-

tion of the blade from the advancing workpiece.

The proper adjustment of the support bearings

is an important part of making accurate cuts and

prevents damage to the blade teeth from contact

with the blade guides.

It is important that the distance of the support

bearing behind the blade is the same as the dis-

tance of the blade guides behind the teeth gullets,

which is typically about 0.016" (see

Figure 45

).

%#%&+

<Ve

%#%&+

<Ve

Hjeedgi

7ZVg^c\

7aVYZ

<j^YZ

Figure 45.

Distance settings of upper support

bearings and blade guides.

Tools Needed

Qty

Hex Wrench 5mm .............................................. 1

Feeler Gauge 0.016" .................................1 Each

Crisp Dollar Bill (Optional) ................................. 1

Tip:

You can use a crisp dollar bill in place of the

feeler gauge for the following procedures. The

thickness of the bill when folded in half twice is

approximately 0.016".

Refer to

Figures 46–47

and the following descrip-

tions to become familiar with the controls to adjust

the support bearings. Then, adjust the surface of

the support bearings approximately 0.016" behind

the blade.

Note:

The support bearing controls are similar for

all models.

Figure 46.

Upper support bearing controls.

A

C

B

Figure 47.

Lower support bearing controls.

C

D

A