Page 2

Drill or punch a 7/8” or 1” hole in the duct at the preferred location and

insert the probe into the hole to mark the enclosure mounting holes.

Remove the unit and drill the two mounting holes.

Clean all drilled holes of debris before mounting the device. Mount

the enclosure to the duct with two sheet metal screws such that the

duct air flow is parallel with the vent holes in the probe (i.e.: air flows

directly into the probe holes). To prevent air leaks, ensure the gasket is

compressed around the probe between the device enclosure and the

air duct. See Figure 1.

The enclosure has a hinged cover with a latch. Open the cover by pulling slightly on the latch on the

bottom of the enclosure, at the same time pulling on the cover. See Figure 2. A 1/2" NPT threaded

connection hole is provided in the side of the enclosure. Screw an EMT connector or cable gland

connector in until tight. A weatherproof conduit or cable gland fitting is recommended. There is an

optional 1/2" NPT to M16 thread adapter and cable gland fitting. See Figure 3.

Two security screws are provided which can be installed to help secure the cover once settings and wiring

connections are complete. See Figure 4.

WIRING

Deactivate the power supply until all connections are made to the device to prevent electrical shock

or equipment damage. Use 16-22 AWG shielded wire for all connections (only ground the shield at the

controller end) and do not locate the device wires in the same conduit with wiring used to supply inductive

loads such as motors. Pull at least six inches of wire into the enclosure and complete the wiring connection

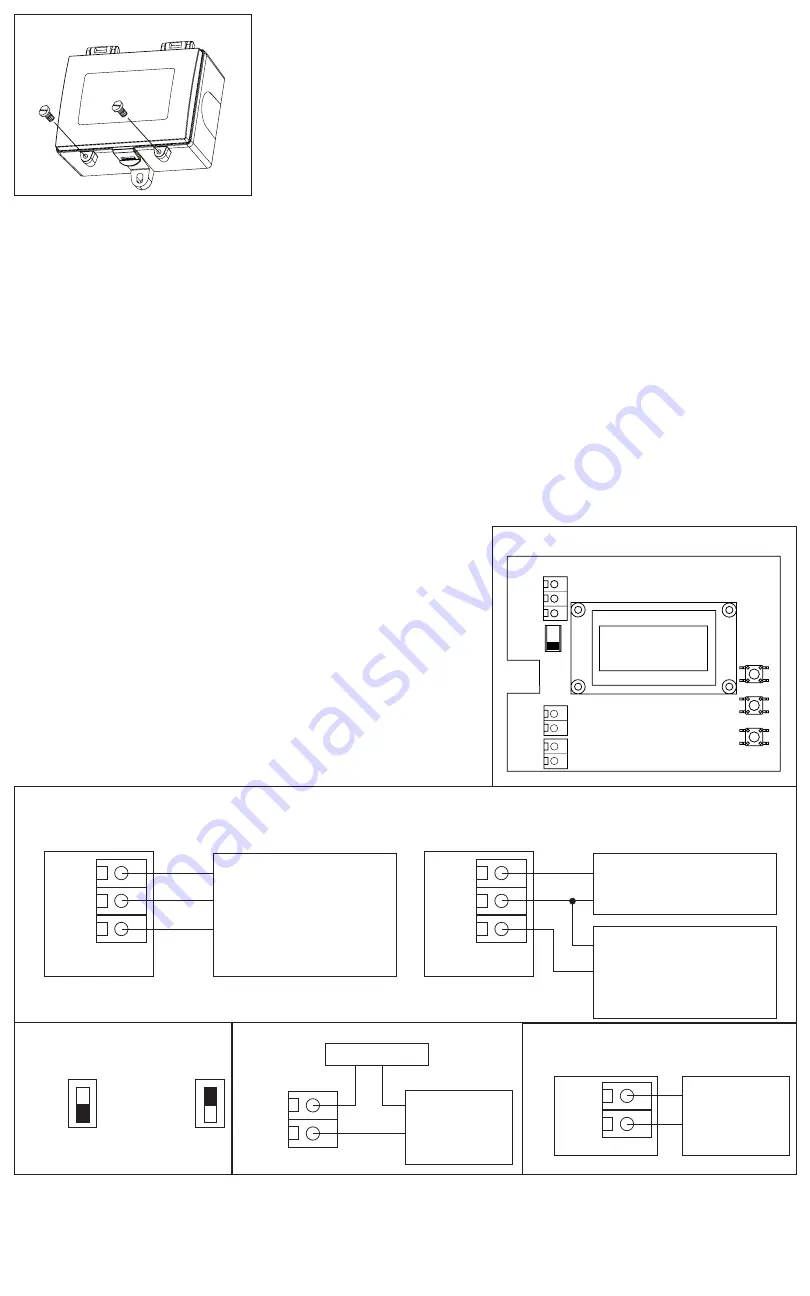

according to the wiring diagram. See Figure 5.

This is a 3-wire sourcing device. Connect the plus DC or the AC voltage hot side to the PWR terminal

and the common is connected to the COM terminal. The device

is reverse voltage protected and will not operate if connected

backwards. It has a half-wave power supply so the supply

common is the same as the signal common. Several devices

may be connected to one power supply and the output signals

all share the same common. Use caution when grounding the

secondary of a transformer or when wiring multiple devices

to ensure the ground point is the same on all devices and the

controller. See Figure 6.

The CO

2

analog output is available on the CO

2

terminal. This

signal is switch selectable for either 4-20 mA or voltage output

(0-5 / 0-10 Vdc) and connects to the controller analog input. See

Figure 7.

Check the controller Analog Input to determine the proper connection before applying power. Both

current and voltage signals are referenced to the COM terminal. The current output operates in the active

mode and does not require a loop power supply (the signal current is generated by the transmitter and

must not be connected to a powered input or device damage will result).

Figure 5

Figure 7

Figure 8

Figure 9

Figure 6

Power Supply

Wiring for CO

2

output signal and

24 Vdc power from controller

Wiring for all output and external 24 Vac power

transformer or external 24 Vac power supply

CO

2

COM

PWR

RELAY

TEMP

CO

2

COM

PWR

Analog Input

COMMON

+24 Vdc

COMMON

Digital Input

Analog Input

COMMON

Analog Input

COMMON

COMMON

24 Vac

Controller

Alarm

Controller

24 Vac Transformer /

Power Supply

mA

VOLT

Current

4-20 mA

Voltage

0-5 or 0-10 Vdc

VOLT

mA

Figure 4

PWR

COM

CO

2

TEMP

UP

DOWN

MENU

RELAY

VOLT

mA

Copyright © Greystone Energy Systems, Inc. All Rights Reserved Phone: +1 506 853 3057 Web: www.greystoneenergy.com

IN-GE-CD2DTXXX-03