UG5 Cable Lubrication System

Greenlee / A Textron Company

4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

5

Specifications

Motor

UG511

.........................

120 VAC, 4 A, 1/3 hp, 3-speed

UG512

.........................

12 VDC, 35 A, 1/3 hp, 3-speed

Battery (UG512)

.........

12 V, 18 Ah, sealed lead acid type,

7.12" W x 3" D x 6.5" H

Fluids

Motor Gears

.....................

Mobil One synthetic grease

Pump Drive Gears

...............

75W-90 synthetic gear oil

Setup

Attaching the Hose

The first time the tool is used, attach the hose to the

pump assembly. Use Teflon

®

tape on the threads of

the hose. Screw the hose into the brass manifold and

tighten.

Setting Up the Pump

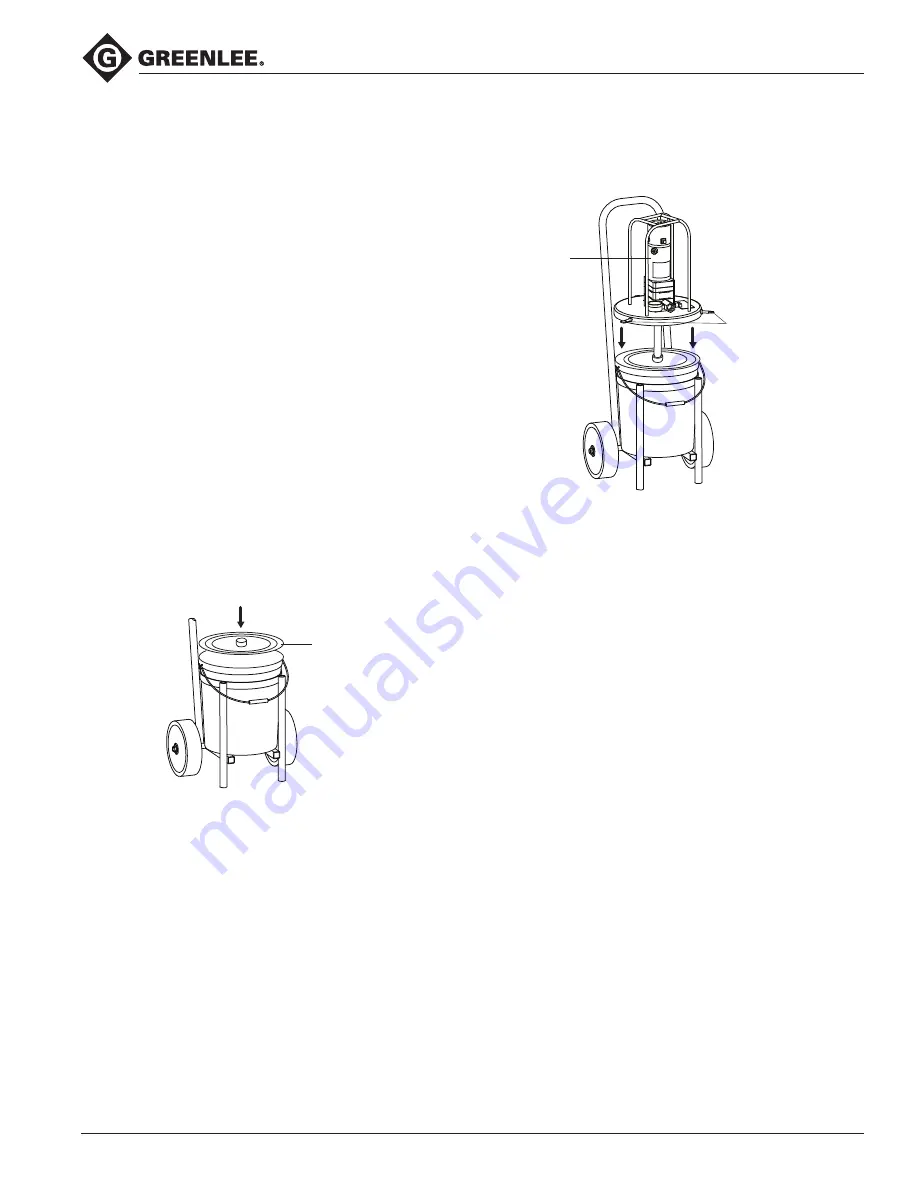

1. Place a 5 gallon bucket of lubricant into the dolly.

2. Remove the lid from the bucket.

3. Place the follower plate inside the bucket, setting it

on top of the lubricant with the hub facing up. Press

down to remove any air pockets.

Follower

Plate

4. Place the pump assembly on top of the bucket, and

slide the suction pipe through the center hole in the

follower plate. (If it is necessary to prime the pump,

refer to “Priming the Pump” below.)

5. Attach the lid to the bucket by tightening the three

thumbscrews.

Pump

Assembly

Thumbscrews

6. Plug in the power cord:

UG511: Plug the power cord into a grounded

•

outlet.

UG512: Plug the power cord into the battery port.

•

7. Attach a lubricant applicator to the end of the hose.

Refer to “Selecting and Attaching Applicators.”

(An applicator must be attached to the hose or

lubricant will not flow.)

8. Press the medium speed button on the top of the

pump unit. Step on the foot switch to start pumping.

The pump may take 30 to 60 seconds to build

pressure and pump lubricant out of the collet. If the

lubricant does not flow, prime the pump.

Priming the Pump

Depending on the viscosity of the lubricant, it may be

necessary to prime the pump.

1. Open the bleed valve opposite the pressure gauge

and run the pump at high speed until lubricant is

seen at the bleed valve. Close the valve.

2. If lubricant still does not flow, pull the pump unit out

of the bucket and re-insert the suction tube into the

follower plate while the pump unit is running at high

speed.