❏

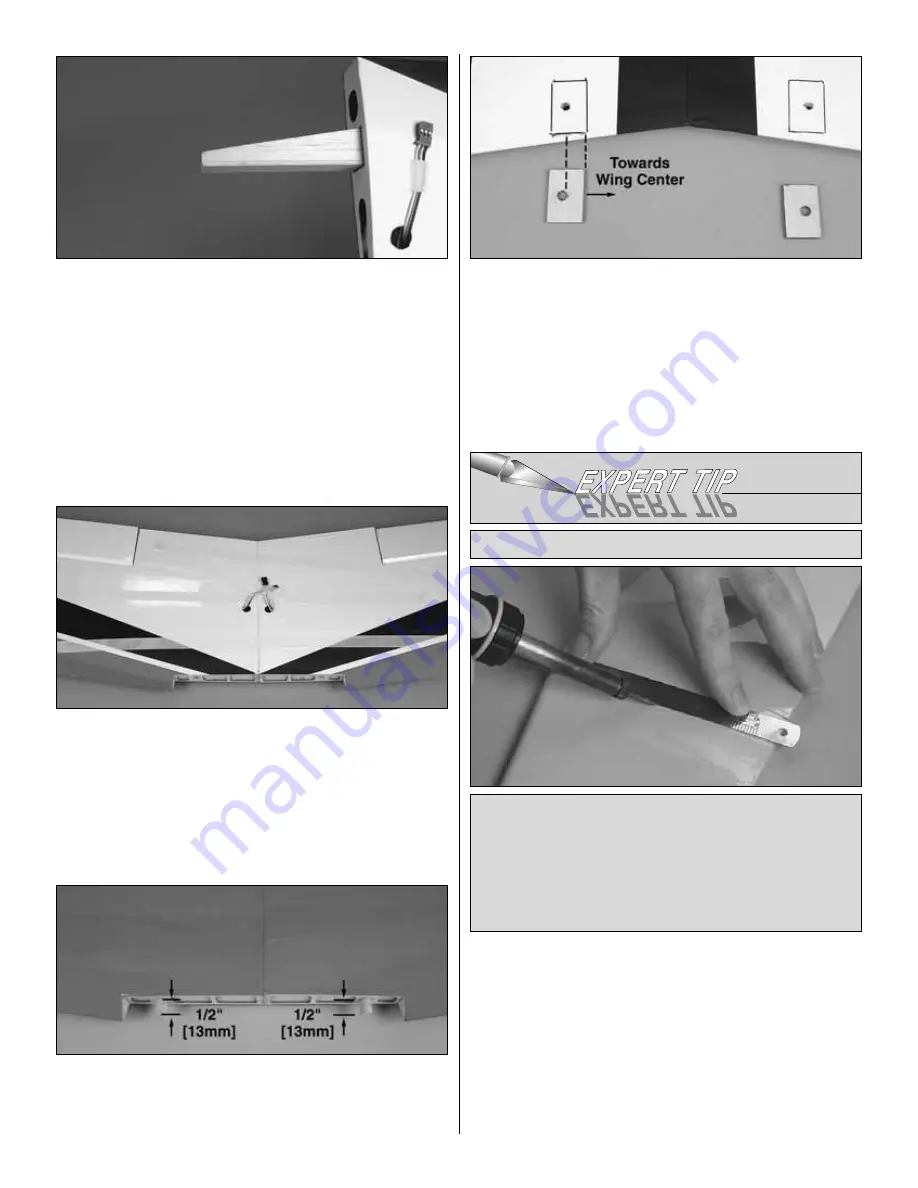

2. Test fit the plywood and balsa wing joiner into the

joiner pocket of both wing halves. When you are satisfied

with the fit of the joiners, glue the joiner into the bottom wing

panels with 30-minute epoxy. When gluing the wing panels

together, be sure to get glue into the joiner pockets in the

wing. This can be done by applying the glue into the pocket

with a small stick. Apply glue to the pocket, the joiner and the

root rib of the wing.

❏

4. Hold the wing together while the glue is curing with

masking tape. Be sure that both of the root ribs are pulled

tightly against one another. Excess epoxy can be cleaned

away with rubbing alcohol and a paper towel.

❏

5. Epoxy two 3/8" x 1-1/4" [9.5 x 32mm] hardwood

leading edge dowels into the two holes in the front of the

wing. The dowel should extend 1/2" [13mm] from the front of

the wing. Set the wing aside until the glue fully hardens.

❏

6. Place the plywood wing bolt mounting plates in

position on the bottom of the wing, over the wing bolt holes.

When positioning the plates be sure the widest part of the

plate is towards the center of the wing. Using a fine tip

marker, trace the outline of the plate onto the wing. Use a

sharp #11 hobby knife or refer to the

Expert Tip that follows

to cut the covering from the wing along the lines you have

marked. Use care to cut only into the covering and not into

the wood.

❏

7. Glue the plates in position onto the wing.

Use a soldering iron to cut the covering from a balsa

sheeted surface. The tip of the soldering iron doesn’t have

to be sharp, but a fine tip does work best. Allow the iron to

heat fully. Use a straightedge to guide the soldering iron at

a rate that will just melt the covering and not burn into the

wood. The hotter the soldering iron, the faster it must

travel to melt a fine cut. Peel off the covering.

How to cut covering from balsa

10