❏

2. Mix up 1 oz. of finishing resin following the

instructions provided in the Great Planes Pro

™

Epoxy

Finishing Resin kit. Use an epoxy brush to liberally coat the

transom of the float.

❏

3. Place the cloth on the resin-coated transom, then

brush the resin through the cloth, removing excess resin

from the center to the edges. Be sure to allow the excess

glass cloth to wrap around the top, sides and bottom of the

float. Some expert modelers squeegee the excess resin off

with a business card or expired plastic credit card. Let the

transom fully cure. Then with a sanding block and fresh 220

grit sandpaper, feather the glass cloth into the float top,

sides and bottom.

❏

4. Apply glass cloth and resin to the deck and sides (one

piece). The cloth should wrap around the bottom 1/4". Hint:

If you cut and position the cloth with the weave running at

45 degrees to the float, the cloth will more readily go

around the sharp bottom corners. Try it!

Another Hint: Build a simple stand to hold the float while you

apply the resin and cloth to the deck and sides. Let the deck

and sides fully cure. Then with a sanding block and fresh 220

grit sandpaper, feather the glass cloth into the bottoms.

❏

5. Following the same procedure outlined above, apply

glass cloth to the bottoms and step. The cloth needs to

overlap the sides 1/4" as shown in the sketch.

❏

6. Lightly sand the entire float with 320-grit sandpaper

being careful not to cut into the glass cloth. Mix up a

2 oz. batch of resin and use a regular camel hair or similar

1" wide paint brush to brush on another coat of resin over

the entire float. For ease of handling, you may do the top

and sides first, then the bottom. If you work quickly you can

save the paint brush by cleaning it with alcohol before the

resin begins to thicken.

❏

7. Carefully sand the entire float with 360-grit sandpaper

and a sanding block, being careful not to sand through

to the cloth. Note: See step 2 under Pushrod Hookup on

page 17 and glue the 1/8" plywood mount block to the deck

after you apply the glass cloth. It is not necessary to cover

the mount block with glass cloth but you should apply resin

over the bare wood. The float is now ready for a coat of

primer. If you have sanded through the second coat of resin

into the cloth, you will have to apply a third coat of resin in

those areas.

❏

8. Apply a coat of primer to the floats. Many expert

modelers have established their favorite brand of paint and

painting methods, but our recommendation is Top Flite

LustreKote Primer. Over glass cloth and resin, one coat of

primer may be sufficient but two coats may be required. You

may dry sand between coats of primer and paint but wet

sanding is preferred – be sure to plug the holes in the deck

for the strut mounts so water does not get inside and do

not sand through the glass cloth.

❏

9. Paint the floats. Again, our recommendation is Top

Flite LustreKote. If you have a good base coat of primer you

may need only one coat of color.

Before you continue, take a break from building and

study the following information to be sure you

understand the positioning of the floats in relation to

the wing and fuselage.

While the following instructions show the Sport Floats on

Great Planes Piper Cubs, there are general tips and

guidelines that apply to all models which will insure proper

handling characteristics in the water and good landing and

takeoff tendencies.

POSITIONING OF FLOATS

12

Summary of Contents for Sport Floats

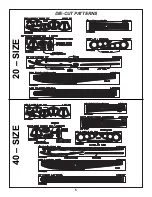

Page 4: ...4 DIE CUT PATTERNS 60 SIZE...

Page 5: ...5 DIE CUT PATTERNS 20 SIZE 40 SIZE...

Page 21: ......