❏

2. Use the landing gear included with your airplane for

the front struts unless you are building a Great Planes

Cub 60. For the Cub 60, you will use the front landing gear

strut and cross brace provided with the floats. For some

models, the front landing gear mounting location on the

fuselage may have to be moved to allow the step in the

float to be placed according to the recommendations.

❏

1. Remove any oily residue from the wire struts by

wiping them with alcohol. Roughen the area to be soldered

with 150-grit sandpaper.

❏

2. Silver solder, such as Great Planes Silver Solder

(GPMR8070), is highly recommended.

❏

3. For soldering the heavy gauge wire struts, higher heat

is required than for normal electrical soldering. A torch is

recommended but some heavy duty soldering irons may

work as well. The higher the temperature of the heating

source applied to the joint, the quicker the solder will flow

and the less time the wire will have to draw heat away from

the area.

❏

4. Avoid a “cold” solder joint which will not have the

shiny appearance of a proper solder joint. A cold joint may

be caused by disturbing the pieces before the molten

solder has solidified or by a joint that never had enough

heat to let the solder flow.

❏

5. Read the instructions provided by the manufacturer of

the solder.

❏

1. Match the shorter front strut with the front cross

brace and the taller rear strut with the rear cross-brace.

The matching struts and cross-braces are the ones that fit

together the best. Note: If you are mounting the floats on a

model other than the Great Planes Cub 60, you may use

the main landing gear included with your model to mount

the front of the floats, and the rear struts included with this

kit to mount the rear of the floats. You may have to relocate

your main landing gear in order to place the step on the

floats at the required position.

❏

2. Wrap each joint neatly and tightly with the

reinforcement wire.

A. For ease of handling, apply thin CA to the joint to

temporarily hold the pieces together.

Solder the Cross-Braces

Notes about Soldering

60 FLOATS ONLY

This section pertains to the 60 Sport Floats only. If

you are building the 20 or 40 Sport Floats, skip to

the “20 And 40 Floats Only” section now.

60 FLOATS ONLY

C. Use 30-minute epoxy to glue the die-cut 1/8" plywood

float mount plate gussets to the fuselage side and

former. Note: The bottom of the gussets may have to be

beveled so they are flush with the bottom of the

fuselage side.

D. Trial fit the aft float mount plate, cut it to the correct

length, then use 30-minute epoxy to securely glue it in

position. When the epoxy has cured, use a sanding block

and 150-grit sandpaper to blend the aft float mount plate

to match the contour of the fuselage bottom. Cover the

bare wood to match you model.

14

Summary of Contents for Sport Floats

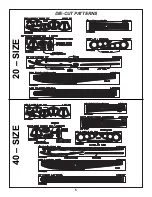

Page 4: ...4 DIE CUT PATTERNS 60 SIZE...

Page 5: ...5 DIE CUT PATTERNS 20 SIZE 40 SIZE...

Page 21: ......