❏

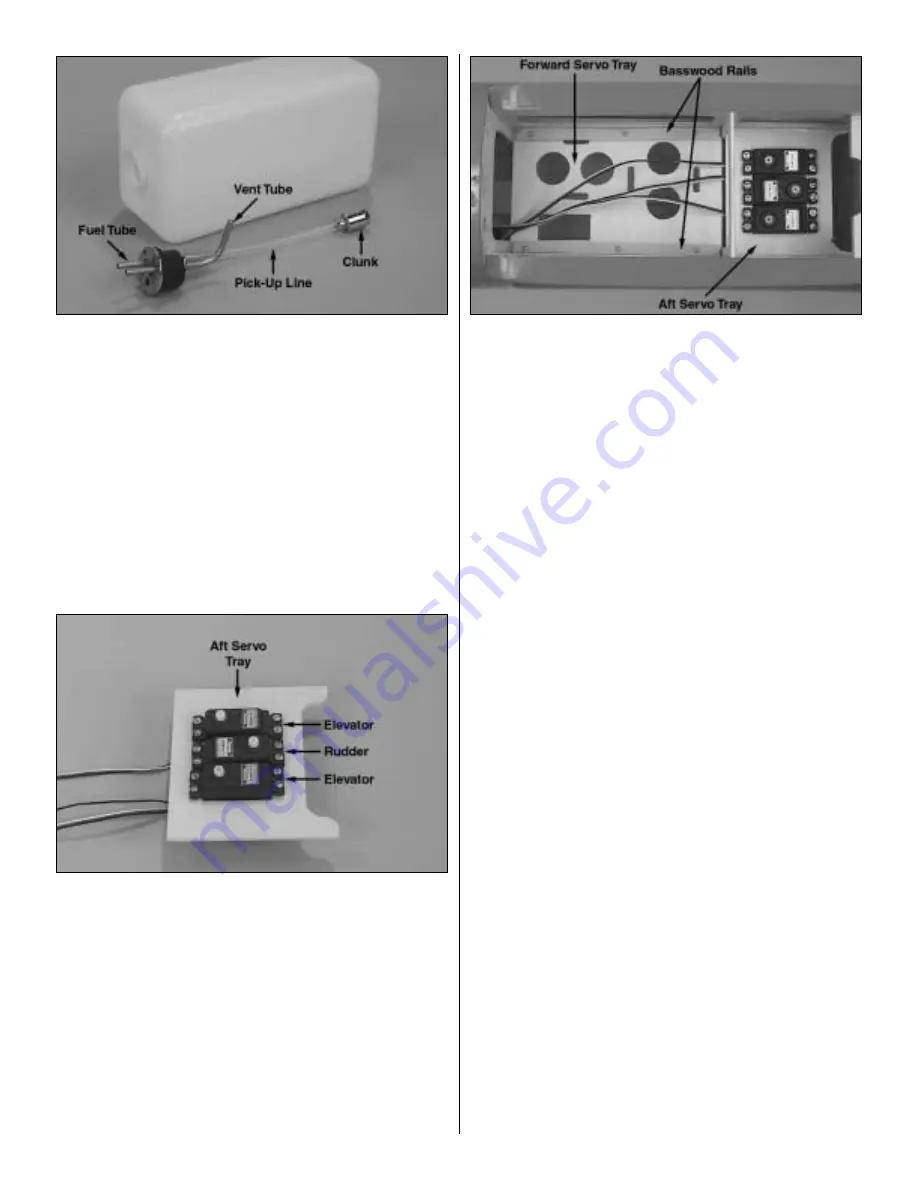

3. Assemble the fuel tank. Arrange the stopper and tubes

as shown in the photo, then fit them into in the tank. Tighten

the screw to expand the stopper, thus sealing the tank. Be

certain the fuel line weight (clunk) at the end of the fuel line

inside the tank does not contact the rear of the tank.

Otherwise, the line may become stuck during flight and

discontinue fuel flow. Remember (or use a felt-tip pen to

mark) which tube is the fuel pick-up tube and which tube is

the vent (that will be connected to the pressure fitting on the

engine muffler).

❏

4. Install the fuel tank so the neck fits through the hole in

the firewall. Be certain that you have installed the tank so

the vent tube inside the tank is pointing upward. Use #64

rubber bands (not included) to hold the tank to the tank floor.

❏

5. Test fit the rudder servo and both elevator servos in

the 1/8" plywood

aft servo tray

. Make adjustments if

necessary to the tray to accommodate your servos. Drill

1/16" holes in the tray for mounting the servos, then add a

few drops of thin CA to the holes and allow to harden. Mount

your servos.

❏

6. Before installing the 1/8" plywood

forward servo tray

,

use a pin to poke a hole through the fuselage sheeting at the

middle

of the

bottom edge

of the hardwood wing strut

mounting blocks on both sides of the fuse. The hole will be

a future reference for mounting the wing struts later on.

Refer to this photo for the following two steps.

❏

7. Securely glue the aft servo tray to the crutches using

epoxy (it may be easier to do this without the servos in the

tray). For additional strength, mix Great Planes Pro Milled

Fiberglass (GPMR6165) into the epoxy. Use clamps to hold

the aft servo tray in position until the epoxy hardens.

❏

8. Removal of the fuel tank will not be possible after the

forward servo tray is glued into position. If you would like to

be able to remove the fuel tank after the forward servo tray

is installed (for future maintenance to the tank), make the

forward servo tray removable. This can be done by using

epoxy to glue 3/16" x 3/8" x 6-3/8" (or a similar size)

basswood rails (not supplied) to the fuse crutches. Drill

three 3/32" holes through both rails before gluing them into

position. Use #2 x 1/2" screws (not supplied) to secure the

tray to the rails. If you prefer not to make the forward servo

tray removable, use epoxy to glue it into position the same

way you did the aft servo tray.

❏

9. Connect the rudder servo to the rudder using the pull-

pull cable system.

❏

10. Cut the covering from the elevator guide tube exits in

both sides of the fuse. Make two

elevator pushrods

by

threading a 4-40 nut and a 4-40 clevis onto two 4-40 x 36"

threaded one-end pushrods. Insert the pushrods into the

guide tubes with the clevises on the aft end.

12