the location for the screw holes. Drill through the marks you

made with a 1/16" [1.6mm] drill bit, drilling through the

plywood plate in the bottom of the flap. Do not drill all the

way through the flap. Install the screw, then remove it.

Harden the holes with thin CA. Mount the nylon control horn

to the flap with two #2 x 3/8" [#2 x 9.5mm] sheet metal screws.

❏ ❏

6. Locate a .074" x 6" [1.9 x 152mm] pushrod wire

threaded on one end. Thread a nylon clevis onto the

threaded end of the wire 20 turns. Install a silicone clevis

retainer onto the clevis. Then, install the clevis to the flap

control horn.

❏ ❏

7. Be sure the flap servo arm is forward, in the position

that will pull the flap into the retracted position. (Plug the

servo into the receiver and turn the radio on to re-position it

properly if you are unsure). Enlarge the hole in the servo

arm with a Hobbico Servo Horn Drill (or a #48 or 5/64"

[2mm] drill bit). Position the flap to the retracted (neutral)

position and align the wire pushrod with the hole in the end

of the servo arm. Using a marker, mark the location where

the wire aligns with the hole in the servo arm. On that mark

make a 90° bend. From the bend measure an additional 3/8"

[9.5mm] and then cut off the excess pushrod wire.

❏ ❏

8. Install the wire into the hole in the servo arm using

a nylon FasLink.

❏

9. Repeat steps 1-8 for the left wing panel.

❏

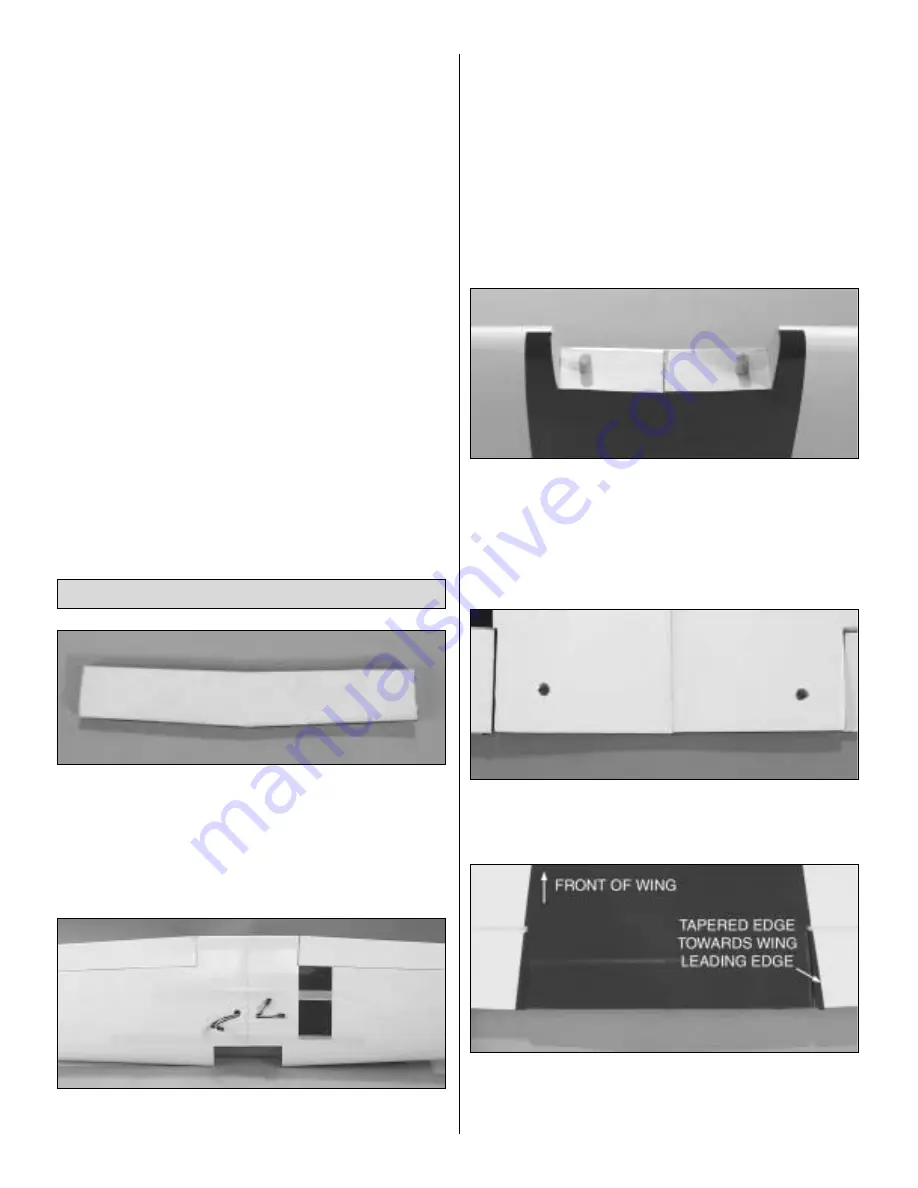

1. Locate the two 1/8" [3mm] plywood wing joiners.

Using 6-minute epoxy, glue them together, forming one 1/4"

[6mm] wing joiner.

❏

2. Test fit the wing joiner into each wing panel, making

sure that it is not too tight. Sand the joiner as needed to get

a good fit.

❏

3. Apply 30-minute epoxy to both sides of the wing joiner,

the joiner pocket in both wing panels and to the root rib of

each wing panel. Push the wing panels together and hold

them in place with masking tape. Before the glue cures, set

the wing flat on your bench and measure the dihedral. The

distance from the top of the bench to the bottom of the wing

should be approximately 4-1/8" [105mm]. Block the wing tip

up while the glue cures.

Note: Due to production techniques

there may be some variance in the actual dihedral of each

model. Our prototypes flew well with the dihedral anywhere

between 3-7/8" and 4-1/4" [98mm and 108mm]. Minor

differences will not affect the flight characteristics.

❏

4. Set the wing aside allowing the glue to cure.

❏

5. Locate two 3/8" x 1-3/4" [9.5mm x45mm] wood

dowels. Apply 6-minute epoxy to the portion of the dowel

that will be inserted into the holes in the leading edge at the

center-section of the wing. Apply epoxy into the holes in the

center-section of the wing. Then, insert the dowels into the

holes until they stop. Wipe away excess glue from the

dowels and set the wing aside to dry.

❏

6. Locate the 1/4" [6mm] holes under the covering at the

trailing edge of the wing center-section. Cut the covering

away on both the top and bottom of the wing.

❏

7. Lay the wing on your bench with the bottom of the wing

facing you. Locate the hardwood wing hold down plate.

Place the hold down plate in position at the wing trailing

edge with the tapered edge of the plate facing the front of

Join the Wings

12

Summary of Contents for Lancair ES

Page 40: ......