5

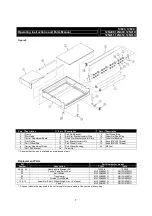

Operating Instructions and Parts Manual

7J823, 7J824

12N408,12N409,12N410

12N411,12N412,12N413

Troubleshooting

Symptom

Cause

Solution

Power switch is

on but not lit

Power disconnection

Sealer circuit breaker has tripped

Power cord is damaged

Check the plug connection or source circuit breaker

Reset the sealer circuit breaker

Replace or repair the cord

Power switch

and Heat LED

are lit, but no

seal is made

Heating element is broken

Spring hook or mounting spring is loose

or has poor contact connections

Terminals of the heating element do not

make a good contact

Limit switch is not engaging

Defective limit switch

Replace the heating element

Clean or tighten spring hook connections

Clean the terminals and adjust if needed

Adjust limit switch position

Replace limit switch

Teflon cloth is

burned or

heating wire

broken

Printed circuit board is damaged

Excessively high heating timer setting.

Replace the printed circuit board

Decrease heating timer setting. Too high a setting

will produce a poor seal and shorten heating element

life.

Seal is broken,

damaged, or

wrinkled

Dirty or damaged silicone rubber or

Teflon tape.

Heat time is set too high.

Insufficient cooling time.

Clean or replace silicone rubber or Teflon tape.

Decrease time and try again.

Increase release timer setting. If release timer is at

its highest setting, manually holding the sealing bar

for 1 to 2 seconds after the beep may be needed.

Partial or

uneven seal

Dirty or damaged silicone rubber or

Teflon tape.

Sealing time is too short.

Seal is not being completed properly.

Clean or replace silicone rubber or Teflon tape.

Increase timer and try again.

Continue to apply pressure to the bar 1-2 seconds

after the red light has gone out.

Bag sticks to

silicone rubber

or heating

element

Sealing time is too long.

Dirty or damaged silicone rubber or

Teflon tape.

Decrease timer and try again.

Clean or replace silicone rubber or Teflon tape.