Operating Instructions and Parts Manual

Operation (continued)

4. A uniform, fully-welded seal should be produced.

NOTE: If seal is damaged, incomplete, or not uniform,

or if the bag is sticking to the sealer, refer to

troubleshooting section of this manual

a good seal is achieved.

5. Place a package on the table of the

such that it is under the upper layer of film

6. Move the package to the L-sealer, unwinding the

film from right to left as you do so.

should be positioned near the front right corner to

minimize excess film.

7. Press firmly down on the bar to begin sealing.

8. At the audible tone, the Release LED turn

and the arm’s electromagnet will

9. Raise the arm and remove the sealed package.

10. Shrink the film using a heat gun or a heated

shrink tunnel.

11. Power off the sealer when finished.

Maintenance

WARNING: Disconnect power before performing any

service or repair.

NOTE: Use original manufacturer’s parts

Weekly Maintenance

Keep the sealing platform clean and remove any

residue found on the platform or Teflon

Silicone spray may be used for this purpose

Check the condition of the silicone

or burn. Damaged silicone rubber will affect the

quality of the seal.

Monthly Maintenance

Place a drop or two of oil on the bearing for the film

roller cradle.

Check screws, nuts, and bolts for loose connections.

Other Maintenance

When changing the Teflon tape, be sure that the

entire surface under the heating element is covered

with Teflon. Bend the excess Teflon

ends to prevent the heating element from breaking

or from grounding to the frame.

4

Operating Instructions and Parts Manual

12N408,12N409,12N410

12N411,12N412,12N413

welded seal should be produced.

If seal is damaged, incomplete, or not uniform,

or if the bag is sticking to the sealer, refer to

troubleshooting section of this manual and repeat until

table of the roller holder

such that it is under the upper layer of film.

sealer, unwinding the

film from right to left as you do so. The package

should be positioned near the front right corner to

to begin sealing.

At the audible tone, the Release LED turns off

will release.

Raise the arm and remove the sealed package.

Shrink the film using a heat gun or a heated

when finished.

before performing any

Use original manufacturer’s parts.

eep the sealing platform clean and remove any

Teflon tape.

spray may be used for this purpose.

e rubber for wear

ubber will affect the

Place a drop or two of oil on the bearing for the film

Check screws, nuts, and bolts for loose connections.

, be sure that the

lement is covered

end the excess Teflon down on both

lement from breaking,

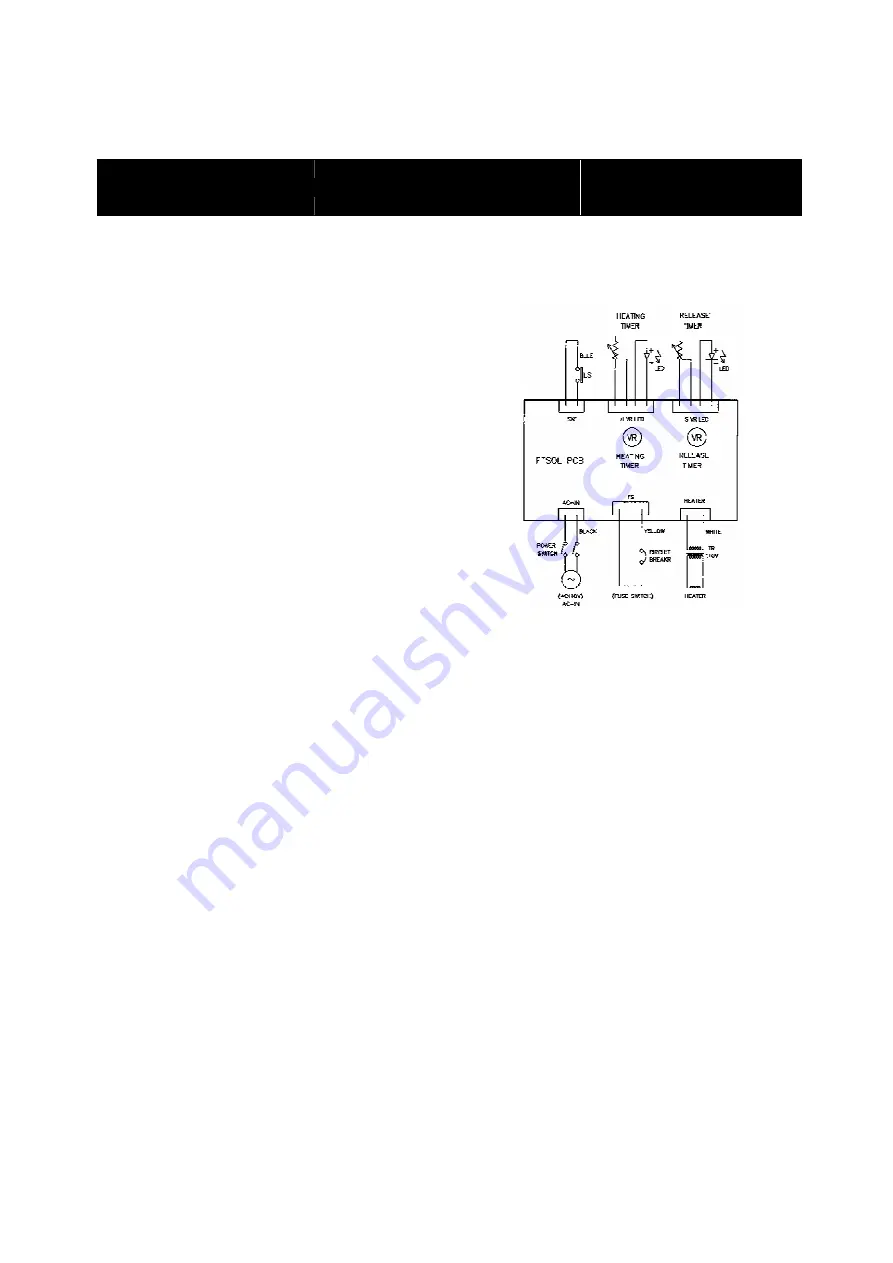

Troubleshooting

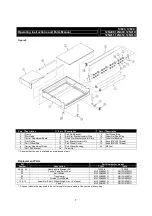

Figure 3

7J823, 7J824

12N408,12N409,12N410

12N411,12N412,12N413