6

Operating Instructions and Parts Manual

7J823, 7J824

12N408,12N409,12N410

12N411,12N412,12N413

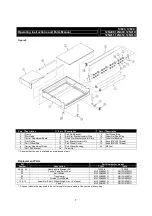

Figure 4

Part

Description

Part

Description

Part

Description

1

Frame

16

Magnet Plate Base

31

Hook Shaft Cover

2

Adjustable Platform

17

Heating Element Base

32*

Limit Switch

3

Control Switch Board

18

Element Radius Spacer

33

Arm Spring

4

Sealing Arm Frame

19

Limit Switch Plate

34*

Silicone Rubber Strip

5

Right Hinge Cover

20

Arm Handle

35

M5*50 Screw

6

Left Hinge Cover

21

Handle Rod

36

Spring

7

Right Hinge Bracket

22

Handle Cap

37

Bushing Sleeve

8

Left Hinge Bracket

23

Hinge/Pivot Pins

38

Foot

9

Electromagnet Cover

24

Element Radius (Copper)

39

20x20 Cap

10

Side Silicone Rubber Strip Base

25

Magnet Plate Base Bracket

40*

Transformer

11

Front Silicone Rubber Strip Base

26*

Heating Wire Element

41*

Printed Circuit Board

12

Sealing Aluminum Base- Side

27

Ceramics

42*

Teflon tape

13

Sealing Aluminum Base- Front

28

Element Hook Cover

43

Electromagnet

14

Sealing wire board holder

29*

Control Panel Switch Set

15

Magnet Plate

30

Element Hook

* - Denotes that the part is available as a replacement part.