7. Additional function of the KLplus/KL24plus and KLbasic/KL24base control unit

30 / 54

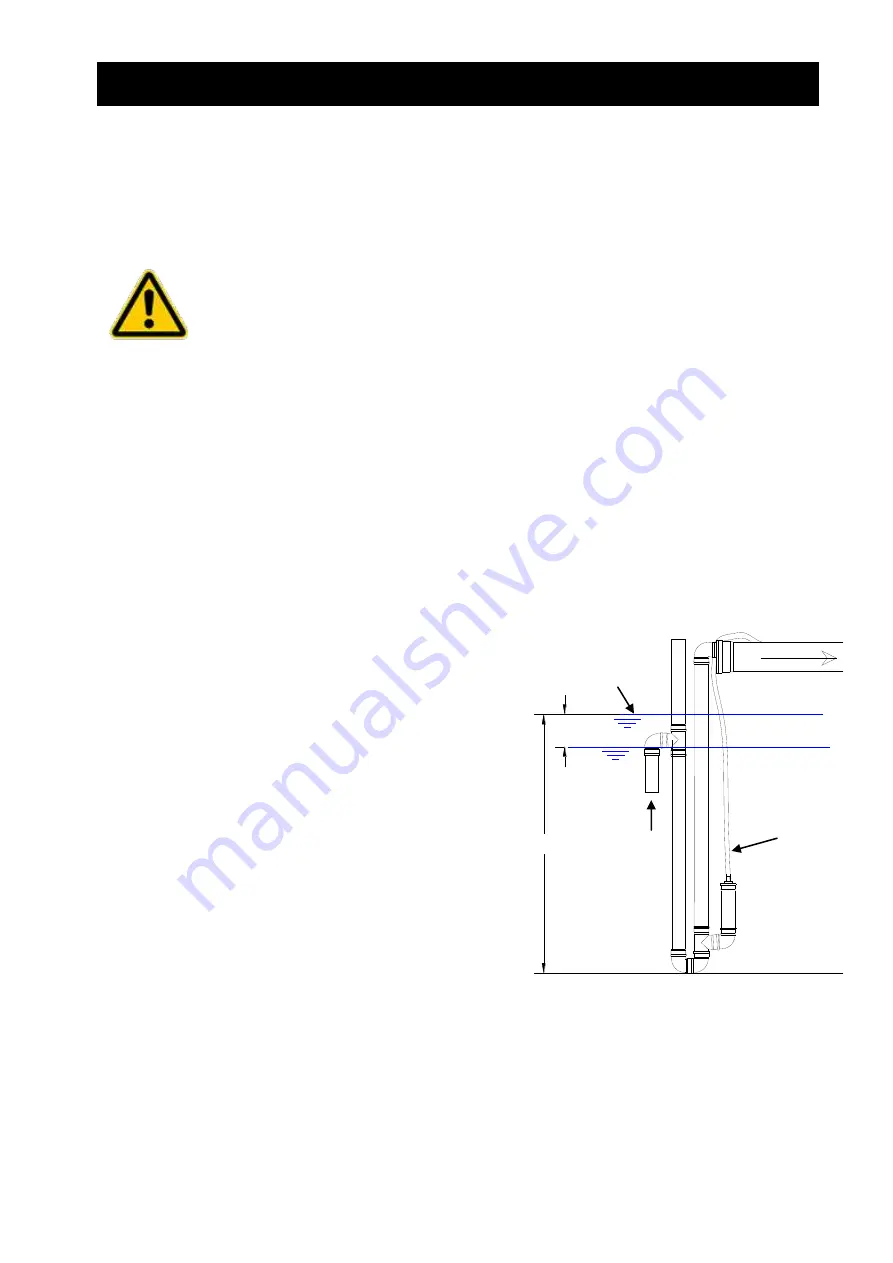

b

a

inflow

Compressed air

water level to activate

detecting under load

outflow

min.

water level

7.

Additional function of the KLplus/KL24plus and KLbasic/KL24base control

unit

Underload detection (KLplus/KL24plus)

7.1

Malfunction

Please note: Level-dependent operation should be activated by a mainte-

nance fitter or an expert. Incorrect calibration of the system could cause it

to operate constantly in economy mode (with cycle pause). Correct cleaning

is not then possible.

This function is deactivated when the system is supplied. When the system is started up, it runs

in automatic mode regardless of the volume of wastewater flowing in.

We would recommend

activating this function after a run-in phase of 3 months at the earliest!

The KLplus control unit is fitted with a pressure sensor as standard and this can be used to es-

tablish the level in the first chamber. This function is used to save energy when the flow of

wastewater is low.

Function

7.1.1

The water level is measured using the pressure in

the feed lifter during the feed phase. If the water

level in the sludge reservoir/buffer (chamber 1)

exceeds a preset level ("Level measurement set-

ting"), the system starts a cleaning cycle. If the

level is not reached, the system goes into cycle

pause for 6 hours. In this mode, the SBR reactor is

only vented sporadically to keep the bacteria alive.

If the preset water level is not reached in the first

chamber after 4 consecutive measurements, the

system pumps water from the reactor into the first

chamber via the excess sludge lifter. After pumping

back, the system measures the water level again.

After a certain time, new feed is therefore supplied

to the reactor even with little or no wastewater supply. The

normal cleaning line can therefore be kept for long periods even in the event of absence or un-

derload.

The number of cleaning cycles undertaken can be queried using the operating hours menu item.

This indicates the cleaning cycles actually undertaken with the cycles performed in automatic

mode (4 a day) as a ratio and as a percentage (25% to 100% utilisation).

Figure 11: Feed lifter