5-2

Spindl-Gard SG-1 and SG-2 Systems

L42110

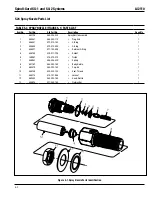

5.2 SG-1 SPRAY NOZZLE

5.2.1

General:

The SG-1 spray nozzle can be disassembled

and individual parts can be ordered. Disassembly

and assembly procedure are provided in paragraphs

5.2.2 and 5.2.3. Figure 5-1 locat ed after the assembly

procedure, shows an exploded view of the spray nozzle

with the associated part numbers.

5.2.2

Spray Nozzle Disassembly Procedure

Turn off pneumatic air and lube systems.

a.

Remove pneumatic and lube connections at spray

b.

nozzle.

CAUTION:

Distance between exposed part of spray nozzle

assembly and machining head should be measured and noted to

within 0.032 inch (0.81 mm). This measurement is necessary for

assembly procedures. Failure to measure and note this distance

may result in component damage caused by ineffective

lubrication.

Measure and note distance between exposed part

c.

of spray nozzle assembly and machining head

hous ing.

CAUTION:

Extreme care should be taken to prevent contamination

from entering through the machine housing during disassembly.

Fail ure to prevent contamination from entering may result in

serious component damage.

Loosen locknut (11, Figure 5-1) and remove spray

d.

nozzle assembly from machining head lubrication

port. Remove and discard thread seal (10) from

nozzle body (8).

Remove end plug (1) with attached nozzle head (12)

e.

from nozzle body (8).

Remove nozzle head (12) from end plug (1), to

f.

remove o-ring (3), o-ring retainer (4), gasket (5),

pis ton (6) and spring (7). Discard o-ring and gasket.

Remove and discard o-ring (2) from end plug (1).

g.

Remove air cap (9) from nozzle body (8).

h.

5.2.3

Spray Nozzle Assembly Procedure

CAUTION:

Extreme care should be taken to prevent contamination

from entering through the machine housing during assembly.

Failure to prevent contamination from entering may result in

component damage.

Install new o-ring (2, Figure 5-1) onto end plug (1).

a.

Insert new o-ring (3), o-ring retainer (4) and piston

b.

(6) into end plug (1).

Insert spring (7) and new gasket (5) into nozzle

c.

head (12).

NOTE

: Ensure spring (7) is properly seated in nozzle head (12) and

on piston (6) before tightening end plug (1).

Thread end plug (1) into nozzle head (12) and

d.

tighten.

Place air cap (9) in nozzle body (8).

e.

Thread end plug (1) with assembled parts into

f.

nozzle body (8) and tighten.

Install locknut (11), washer (13) and new thread

g.

seal (10) onto nozzle body (8).

Thread spray nozzle assembly into machining head

h.

lubrication port until the distance between the top

of the spray nozzle and machine head housing is

equal to that measured during disassembly.

Position thread seal (10) snug against machining

i.

head. Tighten locknut (11).

Install pneumatic and lube connections on spray

j.

nozzle.

Turn on air and lube system. Check spray nozzle for

k.

leaks.

Summary of Contents for SG2

Page 1: ...Spindl Gard SG 1 SG 2 System Operation Service Instructions ...

Page 2: ......

Page 5: ...Spindl Gard SG 1 and SG 2 Systems 1 2 L42110 Figure 1 1 SG 1 System ...

Page 8: ...1 5 Spindl Gard SG 1 and SG 2 Systems L42110 1 6 Blank Figure 1 2 SG 2 System ...

Page 18: ...2 10 Spindl Gard SG 1 and SG 2 Systems L42110 Figure 2 10 Air Flow Switch and Mixing Tees ...

Page 19: ......

Page 26: ......

Page 36: ......