Installation

8

332590A

Update Software, If Needed

NOTE: If the Reactor has a temperature control module

and was built before 2010, a software update is needed.

Otherwise, installation is complete.

25. See step 12 on page 6 to determine if system uses

a temperature control board or a temperature con-

trol module.

26. If the Reactor has a Temperature Control Module,

check Reactor identification label for the date code

which is in the format “G13A”. The number in the

date code is the last two digits of the year built. If the

year built is 2010 or later, a software update is not

needed and installation is complete. Proceed to

Operation on page 9.

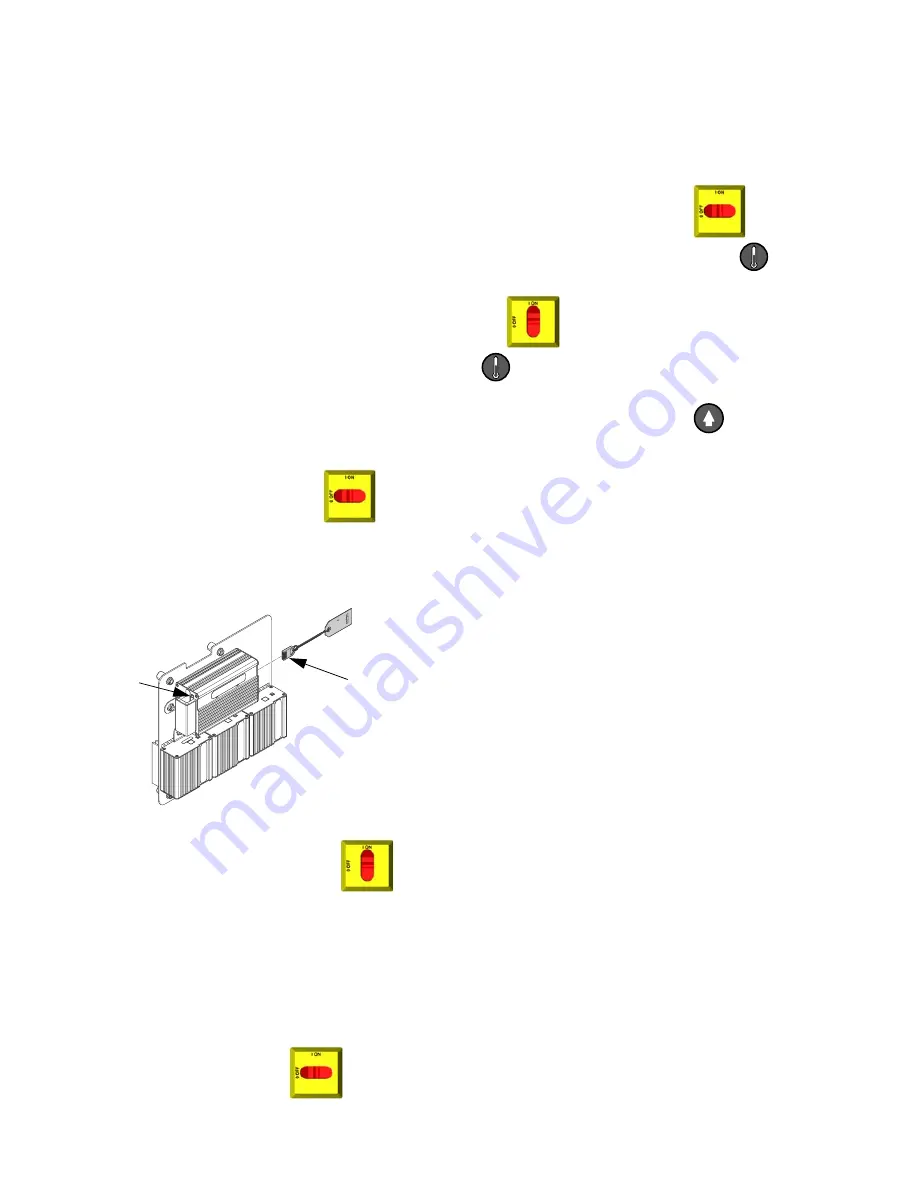

27. Update the software:

a.

Turn Reactor power switch OFF

.

b.

Insert software update token (9) in back of the

Temperature Control Module above the power

wires.

c.

Turn the Reactor power switch ON

.

NOTE: During the software update, the green LED on

the Temperature Control Module will blink rapidly and

the display will show “E99”. When the update is com-

plete, the green light on the Temperature Control Mod-

ule will blink slowly and the display will work normally.

d.

When the software update is complete, turn

Reactor power switch OFF

.

e.

Remove the software update token (9) from the

Temperature Control Module.

28. With Reactor power switch OFF

, press and

hold down the Actual Temperature key

on the

Reactor display and turn the Reactor power switch

ON

. Release the Actual Temperature key

after power has been turned ON.

29. Press the Zone A UP arrow key

four times to

go to the software version.

NOTE: The software version will consist of a number on

each of the three temperature displays.

30. If the software version displayed is 1, 1, 5 or 1, 1, 6

(software versions 1.01.05 and 1.01.06), the soft-

ware did not update. Go back to step 27 to update

the software.

31. If any other software version is displayed, the soft-

ware has been successfully updated.

NOTE: Module is now ready to operate, see page 9.

ti22090a

9

Green

LED