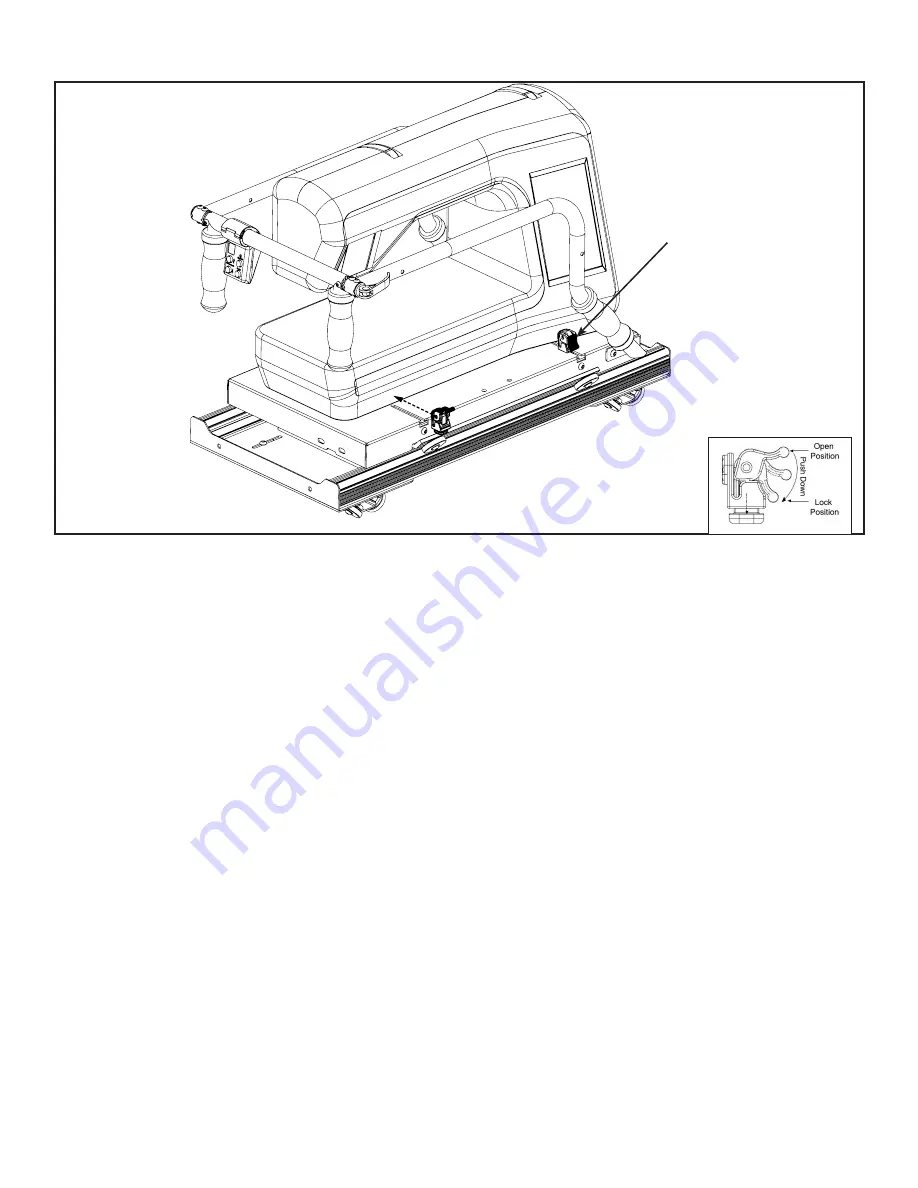

3 Center Machine on Top Plate from side to side and make the back of the throat of Sewing Machine

line up with the vertical part of the handles. Slide each Clamp into the grooves on the Top Plate and

lock against Machine.

Note: Some Larger machines do not require Clamps.

Clamp

21