Conveyor belts

Page 41

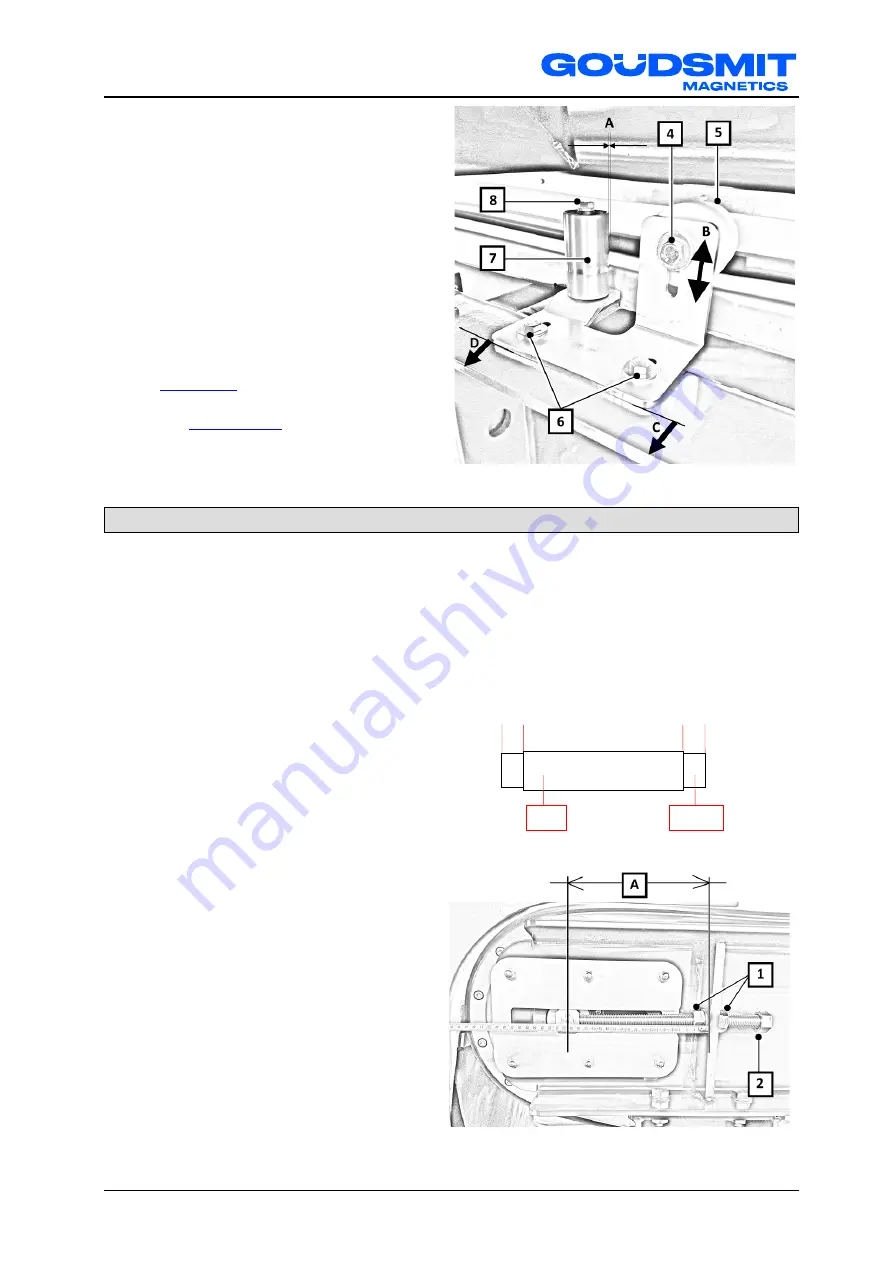

8. Place the belt guide rollers on the frame.

9. Install the bolts (6) hand-tight.

10. Align the wheel of the guide roller (5) so

the guiding snare of the belt falls in the

wheel.

11. Make sure distances C and D are equal

and tighten the bolts (6).

12. Loosen bolt (4), move the wheel so it is

just above the profile and tighten the bolt.

13. Loosen bolt (8), move the roller (7) so

distance A (free space between the belt

and the roller) is 3 mm and tighten the

bolt.

14. Check/correct the tension of the belt, see

15. Check/adjust the alignment of the belt,

see

Adjusting belt alignment

Warning!

It is very important that the belt runs

completely free.

To prevent fast wear (and early

replacement of the belt) make sure the

belt is not touched by the (covers of the)

machine.

1. Measure the distance from the side of the

belt to the end of the roller on the left-

hand side (D) and on the right-hand side

(E).

They must be approximately the same.

D E

2. When the distances are not the same,

adjust them as follows.

3. When the belt needs to move to the left-

hand side, the length of the left-hand

adjustment possibility needs to decrease

so distance (A) will decrease.

In this way the belt is “pushed” towards

the left-hand side.

Note: the more distance (A) is decreased,

the faster the belt will move towards that

side.

4. Loosen locknuts (1), count the number of

turns and rotate the adjustment (2) so

length A decreases.

Belt

Roller