7

10/12 Rev. E

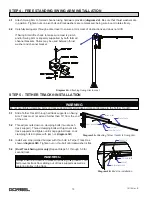

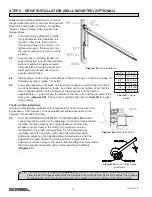

STEP 2 - WALL/COLUMN MOUNTED SWING ARM INSTALLATION

2.1

Determine position of

upper-formed

channel bracket on support structure. Drill

bolt holes (see

chart 1A

and

diagram 1A

, page 4, for bolt diameter and bolt to

support structure.

2.2

Determine position of lower formed channel bracket by measuring distance

between bracket centers; clamp bracket to support structure. Align brackets by

dropping plumb bob (by others) through pivot holes and making sure string is

centered in pivot holes (

diagram 2A

). Shim, if necessary, between mounting

surface and formed channel brackets (shims by others).

2.3

Drill bolt holes for

lower

bracket (see

chart 1A

and

diagram 1A

, page 4,

for bolt diameter) and bolt to support structure. Do not torque bolts until

Swing Arm has been checked for drift (Step 2.5).

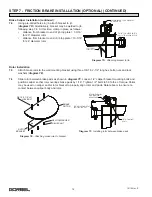

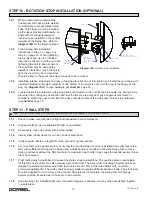

2.4

Attach Swing Arm assembly to formed channel using hardware provided (

diagram 2B

). Be sure that thrust

washers are in position. Tighten nuts on pivot bolt until lockwashers are compressed, being sure boom

freely rotates.

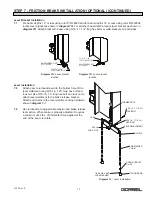

2.5

Carefully swing arm through entire travel to ensure boom is clear of obstructions and does not drift.

If Swing Arm drifts

, support structure may be inadequate and/or shims may be required between mounting

surface and channel brackets (refer to

Step 2.2

for pivot mounting assembly alignment).

2.6

Torque mounting bolts (grade 5 or better, by others) to manufacturer’s specifications.

2.7

Proceed to Step 5 on page 10.

TIP:

Upper and lower formed channel (brackets) are identical unless a rotation stop is welded to the bracket. In

this case, the rotation stop bracket is the upper bracket (refer to Step 10, page 16).

STOP!

Do not proceed if your support structure does not meet the loading requirements determined in Step 1.4.

Diagram 2A.

Plumbing

formed channel brackets.

Diagram 2B.

Attaching Swing Arm assembly to formed channel.