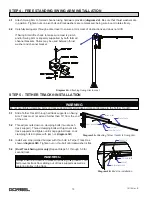

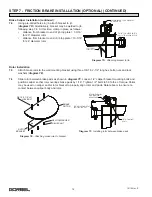

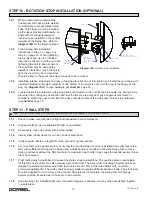

STEP 10 - ROTATION STOP INSTALLATION (OPTIONAL)

10.1

When ordered with a rotation stop,

one bracket will have a plate welded

to it with slots to accept rotation stop

bolts. This bracket must be installed

as the upper bracket. Additionally, an

angle with mounting hardware is

included to be installed on the vertical

member of the Swing Arm. Refer to

diagram 10A

for the following steps.

10.2

Follow Swing Arm installation

instructions in Step 2 on page 7 or

Step 4 on page 10. When tightening

the top pivot bolt, use the included

insert as a socket to hold the nut while

tightening the bolt (a deep socket or

other method may be used at the

installer’s discretion). Once the bolt is

tight, the insert may be removed but

should be kept in the event the bolt ever needs to be removed.

10.3

Install the rotation stop studs and nuts in the stop plate but do not fully tighten yet. Install the stop angle with

included hardware and adjust vertically so the bottom of the angle is even with the top of the flange on the

stop nut (

diagram 10A

). Torque hardware per

chart

8A

, page 14.

10.4

Locate rotation stop hardware in the stop plate such that when the nut hits the stop angle, the Swing Arm is

prevented from hitting any obstruction and that the fall zone is away from any dangerous machinery or

conditions. Orient the nuts so the flat of the hex contacts the flat of the stop angle. Torque stop hardware

per

chart 8A

, page 14.

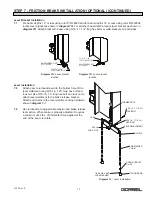

STEP 11 - FINAL STEPS

11.1

Check to make sure all bolts are tight and lockwashers are compressed.

11.2

Grease all fittings (use Lubriplate #630-AA or equivalent).

11.3

If necessary, touch up system with paint provided.

11.4

Install yellow rubber tracdoms on open ends of steel track.

11.5

Verify capacity labels are legible from the ground or egress location.

11.6

For more than a one worker system, verify that the required brake or drive is installed and verify that only a

SRL with sufficient extra payout is being used. Additional line is required to allow the Swing Arm to move

during a fall event without the SRL reaching its maximum length which may cause the second worker to lose

his or her balance.

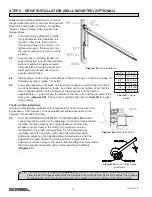

11.7

Proof testing may be performed if required by state or local jurisdictions. The qualified person responsible

for this fall arrest system may also request a proof load test. The Swing Arm Anchorage System has been

designed to withstand a static proof load test not to exceed 125% of the rated MAAF with no visible

permanent deformation. The trolley shall be slowly loaded to avoid additional dynamic loads. The proof load

should be applied for a minimum of one minute. After this test is complete, the Swing Arm Anchorage

System shall be inspected as if a fall event had occurred.

11.8

Keep Packing List, Installation Manual, General Arrangement Drawing, and any other inserts filed together

in a safe place.

A

ROTATION

STOP HARDWARE

(STUD AND NUTS)

(ONLY ONE SHOWN)

HEX INSERT

STOP ANGLE

STOP PLATE

PIVOT BOLT

STOP ANGLE

HARDWARE

B

ALIGN STOP ANGLE

WITH ROTATION STOP NUT

Diagram 10A.

Rotation stop installation.

16

10/12 Rev. E

TIP:

Do not throw away this manual: the maintenance schedule is on the back cover.