INTRODUCTION

Thank you for choosing a Gorbel® G-Force® BX Intelligent Lifting Device (ILD)** to solve your material handling

needs. The innovative design and heavy-duty construction of the G-Force® BX ILD will provide a superior quality

product that will offer years of long-term value. A Gorbel® G-Force® BX ILD will provide many years of dependable

service by following the installation and maintenance procedures described herein.

** U.S. PATENT NO’S: 5,865,426, 6,386,513, & 6,886,812, OTHER PATENTS PENDING

Dimensions contained in this installation manual are for reference only and may differ for your particular

application.

Normal safety precautions:

These include, but are not limited to:

•

Checking for obstructions in crane and hoist travel.

WARNING

Only competent erection personnel familiar with standard fabrication practices should be employed to

install the G-Force® ILD because of the necessity of properly interpreting these instructions. Gorbel is not

responsible for the quality of workmanship employed in the installation of this hoist according to these

instructions. Contact Gorbel, Inc., at 600 Fishers Run, P.O. Box 593, Fishers, New York 14453, 1-585-924-

6262, for additional information, if necessary.

WARNING

Equipment described herein is not designed for, and should not be used for, lifting, supporting or

transporting humans. Failure to comply with any one of the limitations noted herein can result in serious

bodily injury and/or property damage. Check Federal, State and Local regulations for any additional

requirements.

WARNING

Prior to installation, consult a qualified structural engineer to determine if your support structure is

adequate to support the loadings created during normal operation of the G-Force® ILD.

WARNING

Reference American Institute of Steel Construction (AISC) Manual of Steel Construction (9th edition), Part 5,

Specification for Structural Joints using ASTM A325 or A490 Bolts (section 8.d.2) for proper procedure to

follow when using any torque tightening methods.

WARNING

Do not field modify the G-Force® BX ILD in any way. Any modification without the written consent of

Gorbel, Inc., will void warranty.

WARNING

The unique serial number for this unit can be found on the front cover of this manual and on the ID

nameplate sticker attached to the back bottom of the G-Force® ILD Actuator assembly cover. Always have

this serial number available during all correspondence regarding your G-Force® BX, ILD, or when ordering

repair parts.

WARNING

The Jog Switch buttons are for system maintenance and load testing use only, and should not be

manipulated during normal operation of the G-Force® BX ILD. Operation of the Jog Switch buttons during

normal operation increases the risk of personal injury to the operator.

5

4/04-Rev. S

®

Summary of Contents for 150 BX G-Force

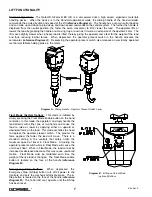

Page 26: ...Figure A3 bottom Figure A4 top 150 BX Actuator Assembly 25 4 04 Rev S ...

Page 27: ...Figure A5 150 BX Actuator Assembly 26 4 04 Rev S ...

Page 28: ...Figure A6 150 BX Actuator Assembly 27 4 04 Rev S ...

Page 29: ...Figure A7 bottom Figure A8 top 150 BX Actuator Assembly 28 4 04 Rev S ...

Page 30: ...Figure A9 bottom Figure A10 top 150 BX Actuator Assembly 29 4 04 Rev S ...

Page 31: ...Figure A11 bottom Figure A12 top 150 BX Actuator Assembly 30 4 04 Rev S ...

Page 32: ...Figure A13 150 BX Actuator Assembly 31 4 04 Rev S ...

Page 33: ...Figure A14 150 BX Actuator Assembly 32 4 04 Rev S ...

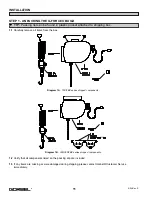

Page 35: ...Figure B3 bottom Figure B4 top 300 380 BX Actuator Assembly 34 4 04 Rev S ...

Page 36: ...Figure B5 300 380 BX Actuator Assembly 35 4 04 Rev S ...

Page 37: ...Figure B6 300 380 BX Actuator Assembly 36 4 04 Rev S ...

Page 38: ...Figure B7 bottom Figure B8 top 300 380 BX Actuator Assembly 37 4 04 Rev S ...

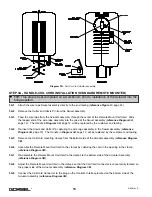

Page 39: ...Figure B9 bottom Figure B10 top 300 380 BX Actuator Assembly 38 4 04 Rev S ...

Page 40: ...Figure B11 bottom Figure B12 top 300 380 BX Actuator Assembly 39 4 04 Rev S ...

Page 41: ...40 Figure B13 300 380 BX Actuator Assembly 4 04 Rev S ...

Page 42: ...Figure B14 300 380 BX Actuator Assembly 41 4 04 Rev S ...

Page 44: ...Figure C3 Standard Handle Assembly 43 4 04 Rev S ...

Page 45: ...Figure C4 Standard Handle Assembly 44 4 04 Rev S ...

Page 46: ...Figure C5 bottom Figure C6 top Standard Handle Assembly 45 4 04 Rev S ...

Page 47: ...Figure C7 bottom Figure C8 top Standard Handle Assembly 46 4 04 Rev S ...

Page 48: ...Figure C9 bottom Figure C10 top Standard Handle Assembly 47 4 04 Rev S ...

Page 49: ...Figure C11 bottom Figure C12 top Standard Handle Assembly 48 4 04 Rev S ...

Page 50: ...Figure C13 Standard Handle Assembly 49 4 04 Rev S ...

Page 52: ...Figure D3 bottom Figure D4 top Float Mode Handle Assembly 51 4 04 Rev S ...

Page 53: ...Figure D5 bottom Figure D6 top Float Mode Handle Assembly 52 4 04 Rev S ...

Page 54: ...Figure D7 bottom Figure D8 top Float Mode Handle Assembly 53 4 04 Rev S ...

Page 55: ...Figure D9 bottom Figure D10 top Float Mode Handle Assembly 54 4 04 Rev S ...

Page 56: ...Figure D11 Float Mode Handle Assembly 55 4 04 Rev S ...

Page 58: ...Figure E2 Air Coil Cord Assembly Standard Float Mode 57 4 04 Rev S ...

Page 59: ...Figure E3 Remote Mount Coil Cord Standard Float Mode 58 4 04 Rev S ...

Page 60: ...Figure E4 Air Remote Mount Coil Cord Standard Float Mode 59 4 04 Rev S ...

Page 61: ...APPENDIX F CONTROLS SCHEMATIC DRAWINGS Figure F1 Remote Load Cell Assembly 60 4 04 Rev S ...

Page 62: ...Figure F2 BX Controls Schematic 61 4 04 Rev S ...

Page 64: ...Figure G2 BX G Force 300 380 Overall Dimensions 63 4 04 Rev S ...

Page 67: ...Figure I2 300 380 Standard Inline Component Layout 66 4 04 Rev S ...

Page 68: ...Figure I3 Standard Remote Mount Component Layout 67 4 04 Rev S ...