27

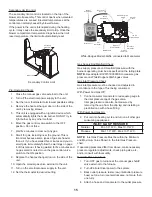

X = Outside of Temperature Rise Range - Not Recommended.

NOTE:

The shaded area indicates ranges in excess of maximum external static pressure allowable when heating. For satisfactory operation, external

static pressure should not exceed 0.5" w.c.

BLOWER PERFORMANCE DATA

CFM

WATTS

RISE

CFM

WATTS

RISE

CFM

WATTS

CFM

WATTS

CFM

WATTS

0.1

616

51

55

845

105

53

859

94

885

103

1048

140

0.2

581

60

58

809

116

56

810

102

836

111

999

148

0.3

535

69

63

774

124

58

761

109

788

118

950

155

0.4

476

79

X

736

134

61

713

117

740

126

901

163

0.5

422

87

X

695

140

65

664

125

692

134

852

171

0.6

365

95

X

646

148

X

615

133

643

142

803

179

0.7

334

101

X

580

161

X

---

---

---

---

---

---

0.8

300

103

X

532

167

X

---

---

---

---

---

---

CFM

WATTS

RISE

CFM

WATTS

RISE

CFM

WATTS

CFM

WATTS

CFM

WATTS

0.1

708

57

50

1004

129

52

859

94

885

103

1048

140

0.2

659

65

57

955

137

54

810

102

836

111

999

148

0.3

610

72

63

906

145

56

761

109

788

118

950

155

0.4

561

80

X

857

153

59

713

117

740

126

901

163

0.5

512

88

X

808

160

63

664

125

692

134

852

171

0.6

---

---

---

760

168

X

615

133

643

142

803

179

0.7

---

---

---

---

---

---

---

---

---

---

---

---

0.8

---

---

---

---

---

---

---

---

---

---

---

---

CFM

WATTS

RISE

CFM

WATTS

RISE

CFM

WATTS

CFM

WATTS

CFM

WATTS

0.1

997

147

45

1276

284

47

1059

137

1071

142

1333

234

0.2

965

155

47

1238

284

48

1008

144

1023

149

1285

242

0.3

922

165

49

1206

289

50

956

151

976

157

1237

250

0.4

886

173

51

1164

302

52

908

158

928

164

1189

257

0.5

835

182

54

1131

314

53

857

166

880

172

1141

265

0.6

781

188

58

1086

319

55

784

175

832

180

1094

273

0.7

731

200

62

1038

319

58

732

180

784

187

---

---

0.8

677

202

X

984

322

61

673

188

736

195

---

---

CFM

WATTS

RISE

CFM

WATTS

RISE

CFM

WATTS

CFM

WATTS

CFM

WATTS

0.1

1059

137

49

1260

213

55

1059

137

1071

142

1333

234

0.2

1008

143.5

52

1212

221

57

1008

143.5

1023

149

1285

242

0.3

956

151

54

1165

229

59

956

151

976

157

1237

250

0.4

908

157.5

57

1117

236

62

908

157.5

928

164

1189

257

0.5

857

165.5

60

1069

244

64

857

165.5

880

172

1141

265

0.6

784

175

63

1021

252

68

784

175

832

180

1094

273

0.7

732

180

69

973

259

70

732

180

784

187

---

---

0.8

673

187.5

72

-

-

-

673

187.5

736

195

---

---

T5

Cooling Speed

*PD1424060M41A* - Rise Range: 35° - 65°

T1

1

ST

Stage Heating Speed

T2

2

nd

Stage Heating Speed

T3

Cooling Speed

E.S.P

T1

1

ST

Stage Heating Speed

*PD1430090M41B* - Rise Range: 45° - 75° F

T2

2

nd

Stage Heating Speed

T3

Cooling Speed

T4

Cooling Speed

T4

Cooling Speed

T5

Cooling Speed

E.S.P

*PD1424070M41B* - Rise Range: 35° - 65° F

E.S.P

T1

1

ST

Stage Heating Speed

T2

2

nd

Stage Heating Speed

T3

Cooling Speed

T4

Cooling Speed

T5

Cooling Speed

*PD143080M41A* - Rise Range: 35° - 65°

E.S.P

T1

1

ST

Stage Heating Speed

T2

2

nd

Stage Heating Speed

T3

Cooling Speed

T4

Cooling Speed

T5

Cooling Speed

Summary of Contents for APD 14 M Series

Page 23: ...23 UNIT DIMENSIONS...