17

Temperature Rise Check

NOTE:

Air temperature rise is the temperature difference

between supply and return air.

With a properly designed system, the proper amount of

temperature rise will normally be obtained when the unit

is operated at rated input with the recommended blower

speed.

If the correct amount of temperature rise is not obtained, it

may be necessary to change the blower speed. A higher

blower speed will lower the temperature rise. A slower

blower speed will increase the temperature rise.

NOTE:

Blower speed MUST be set to give the correct air

temperature rise through the unit as marked on the rating

plate.

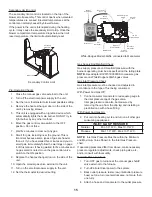

External Static Pressure Check

The total external static pressure must be checked on this

unit to determine if the airflow is proper.

1. Using a digital manometer measure the static pressure

of the return duct at the inlet of the unit, (Negative

Pressure).

Total External Static

2. Measure the Static pressure of the supply duct,

(Positive Pressure).

3. Add the two readings togther.

NOTE:

Both readings may be taken simultaneously

and read directly on the manometer if so desired.

4. Consult proper table for quantitu of air.

If the external static pressure exceeds the minimum or

maximum allowable statics, check for closed dampers, dirty

filters, undersizd or poorly laid out ductwork.

Blower Speed Adjustments

WARNING

T

O AVOID PERSONAL INJURY OR DEATH DUE TO ELECTRIC SHOCK, REMOVE

ELECTRICAL POWER FROM THE UNIT

B

EFORE CHANGING SPEED TAPS ON THE

B

LOWER MOTOR.

Refer to the wiring diagram and airflow data in the appendix

to verify speed tap settings.

Depending upon the model, blower speeds are changed

at the indoor blower. The ignition control board has four

blower speeds: LOW HEAT, HI HEAT, LOW COOL and

HIGH COOL.

NOTE:

FAN ONLY energizes at LOW HEAT speed.

The *PD14 models are equipped with EEM motors. EEM

motors are constant torque motors with very low power

consumption. This motor is energized by 24VAC. Adjust

the CFM for the unit by changing the 24VAC leads to the

speed terminal block on the motor.

NOTE: Heating airflow must be adjusted to provide the

temperature rise shown on rating plate. A higher speed

tap may not provide more airflow. Blower speeds are

programmed to deliver adequate airflow at rated external

static pressure (ESP). Refer to airflow table provided in the

Appendix for details.

Lead

Color

Speed

Tap

Definition

Lead

Color

Speed

Tap

Definition

White

T1

Low

Speed Heat

T3

Cool/HP

Optional Low

Speed

Brown

T2

High

Speed Heat

Yellow

T4

Cool/HP

Speed

T5

High Static

GAS HEATING

COOLING

Limit Check

Check limit control operation after 15 minutes of operation

by blocking the return air grille(s).

1. After several minutes the main burners must go OFF.

Blower will continue to run.

2. Remove air restrictions and main burners will relight

after a cool down period of a few minutes.

Adjust the thermostat setting below room temperature.

1. Main burners must go OFF.

2. Circulating Air Blower will continue to run for 90, 120,

150 or 180 seconds, depending on the setting.

NOTE:

If necessary, adjust fan OFF delay settings to obtain

satisfactory comfort level.

Summary of Contents for APD 14 M Series

Page 23: ...23 UNIT DIMENSIONS...