With different combinations of FEED PAUSE and CANCEL keys, the printer can perform various

functions as follows:

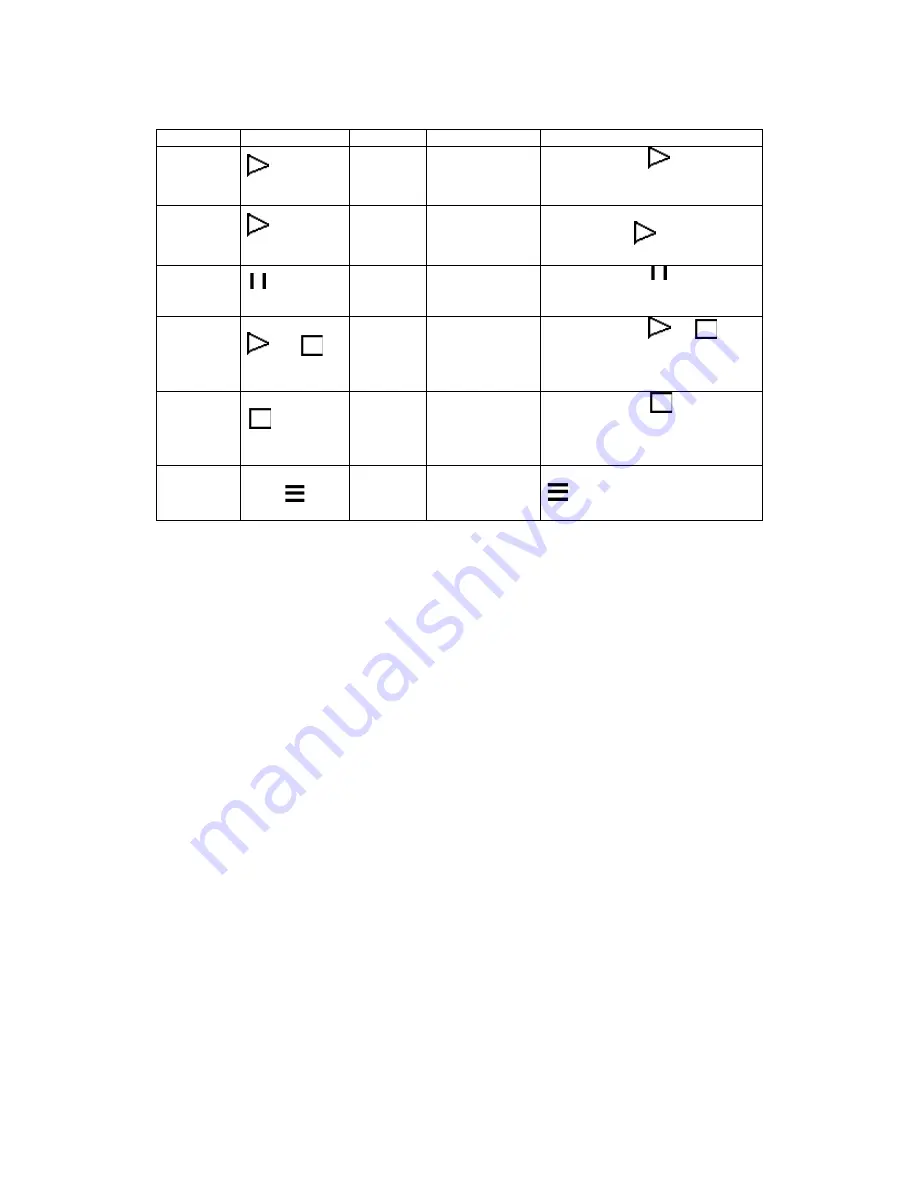

Item

Key

Beep

LCD Message

Description

Self test

+ Power

on

3 beeps

Self test

Press and hold

key and turn

on the printer until the buzzer

beeps 3 times.

Dump

mode

+ Power

on

3 beeps

Æ

1 beep

Now in Dump

Mode

After entering Self test Mode,

keep holding

key until the

buzzer beep once.

Auto

sensing

+ Power

on

3 beeps

Auto sensing

Mode

Press and hold

key and turn

on the printer until the buzzer

beeps 3 times.

Go to

default

+

+

Power on

2 beeps

twice

Go to default

Press and hold

&

keys

and turn on the printer until the

buzzer beeps 2 times. The

printer setting will go to default.

Download

mode

+ Power

on

1 beep

DL MODE

Vx.xx

Press and hold

key and

turn on the printer until the

buzzer beeps once. This mode is

only for firmware downloading.

Setting

mode

3 beeps

Setting mode

When Power on, press and hold

key about 3 to 4 seconds

until the buzzer beep 3 times.

EZPi-1000 User’s Manual

19