Adjusting the hot water temperature 8

0020201109_01 Energy Installation and maintenance instructions

21

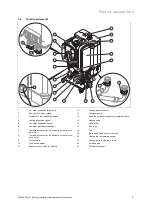

7.3

Setting the bypass valve

1

▶

Turn the adjusting screw

(1)

.

–

Setting the bypass valve in the as-delivered condition:

Open by 3/4 of a turn.

8

Adjusting the hot water temperature

Danger!

Risk of death from Legionella.

Legionella multiply at temperatures below

60 °C.

▶

Ensure that the operator is familiar with all

of the Anti-legionella measures in order

to comply with the applicable regulations

regarding legionella prevention.

9

Inspection and maintenance

9.1

Observing inspection and maintenance

intervals

▶

Comply with the minimum clearances for the inspection

and maintenance. Depending on the results of the in-

spection, it may be necessary to bring maintenance work

forward.

Inspection and maintenance work

–

Overview

9.2

Procuring spare parts

The original components of the product were also certified

as part of the declaration of conformity. If you do not use

certified Glow-worm original spare parts for maintenance

or repair work, this voids the conformity of the product. We

therefore strongly recommend that you install Glow-worm

original spare parts. Information about available Glow-worm

original spare parts is available by contacting the contact

address provided on the reverse of this document.

▶

If you require spare parts for maintenance or repair work,

use only Glow-worm original spare parts.

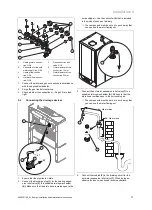

9.3

Gas conversion procedure

1

1.

Disconnect the product from the power mains.

2.

Turn the bolt

(1)

in the direction specified in the table

and by the number of rotations specified in the table.

Setting the gas valve

Turning

clockwise

Turning

anti-clock-

wise

G20

→

G31

G31

→

G20

Energy 35 Store-

A

2.5

2.5

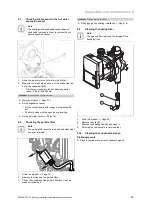

3.

Start up the product with the check programme

(P.01)

and set the value.

–

Setting value for the programme P.01: 100

Check programmes

–

Overview (

→

Page 28)

Note

If the product is in the operating cycle

(ON/OFF), decrease the set value.

4.

Wait until the value that is read is stable.

–

Waiting period for reading a stable value: 2 min

5.

Measure the CO

₂

content at the flue gas analysis point

(2)

.

6.

Compare the measured value with the corresponding

value in the table.

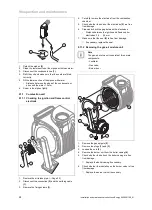

Checking the CO

₂

content

Great

Bri-

tain

Removed

front casing

Natural gas

G20

9

±

0.2 %

Liquid gas

G31

10.1

±

0.2 %

Fitted front

casing

Natural gas

G20

9.2

±

0.3 %

Liquid gas

G31

10.3

±

0.3 %

▽

Set the CO

₂

(

→

Page 19) content as required.