26

Global Manufacturing, Inc

®

800.551.3569

TOLL FREE USA & CANADA

1801 East 22nd Street

501.374.7416

TEL

501.376.7147

FAX

Little Rock, AR 72206 USA

w w w. G l o b a l M a n u f a c t u r i n g . c o m

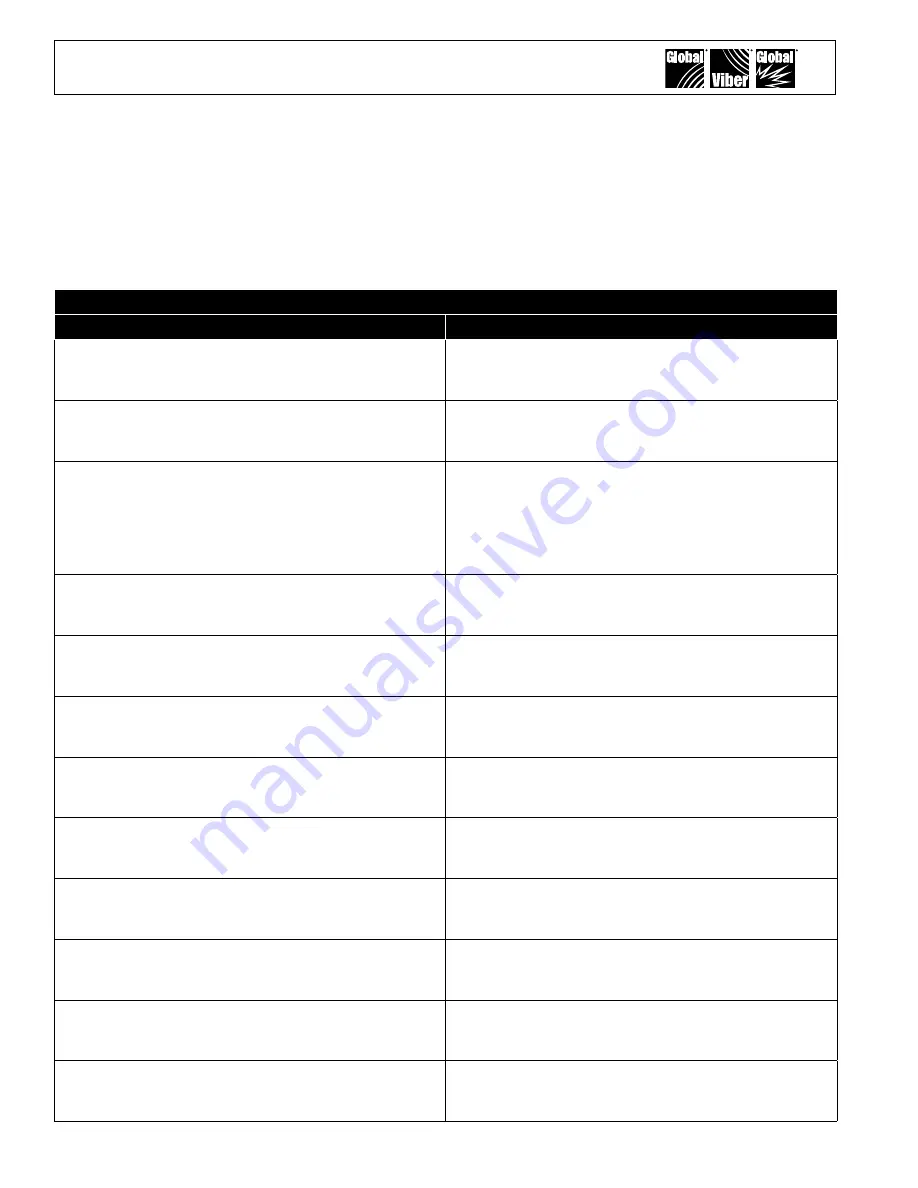

Appendix A - Troubleshooting

Prior to shipment, all Global Air Blasters are tested for pressure and function according to corresponding

pressure vessel regulations and quality manufacturing specifications. Despite the simple and sturdy

construction, malfunctions can occur due to the kind of application, installation, and/or operation. The

following list should help identify the causes of some problems that occur and gives possible solutions

to eliminate those problems.

Control Valve

= 3-Way Normally Open Manual or Solenoid Valve.

Operating Valve = Quick Exhaust Valve.

PROBLEM: Air Blaster discharges with weak or no blast.

PROBABLE CAUSE

SOLUTION

Air leakage in control valve or operating valve.

Check control valve and operating valve for

wear, damage, contamination. Check for system

leaks.

Control or operating valve is malfunctioning.

Check air filtering system. Clean or repair

valves as needed.

Control valve is too far from the Air Blaster, or

the size of the valve is too small.

Control valve must be within 100 feet of the

Air Blaster. If distance is greater than 100 feet

move it closer to the Blaster. Be sure valves are

the recommended size. A ¾" control valve must

be used and connected by a ¾" airline to the

Air Blaster.

Piston lodged in operating valve due to

contamination.

Disassemble and clean operating valve

assembly. Check filter element in filter

regulator.

Low air pressure.

Air Blaster not completely filled before it is

discharged.

With manual firing give the Air Blaster more

time to fill. Increase the between blast time on

the timer. Use a larger diameter fill line.

Sharp bends in the discharge pipe reduce force

output.

Use long radius elbows.

Discharge pipe is blocked with material.

Clean pipe and reposition it to prevent material

from entering.

Discharge pipe is too long.

Air Blaster should be as close as possible to

discharge opening.

Piston is not sealing.

Clean or replace piston and o-ring. Check valve

seat for dents, nicks, etc. The piston and valve

seat must seal.

Pressure vessel (tank) is punctured or cracked.

Replace pressure vessel.

Air Blaster is firing into an area void of material.

Air Blaster discharge should be above the

blockage of material to blast through the

blockage.