10

q

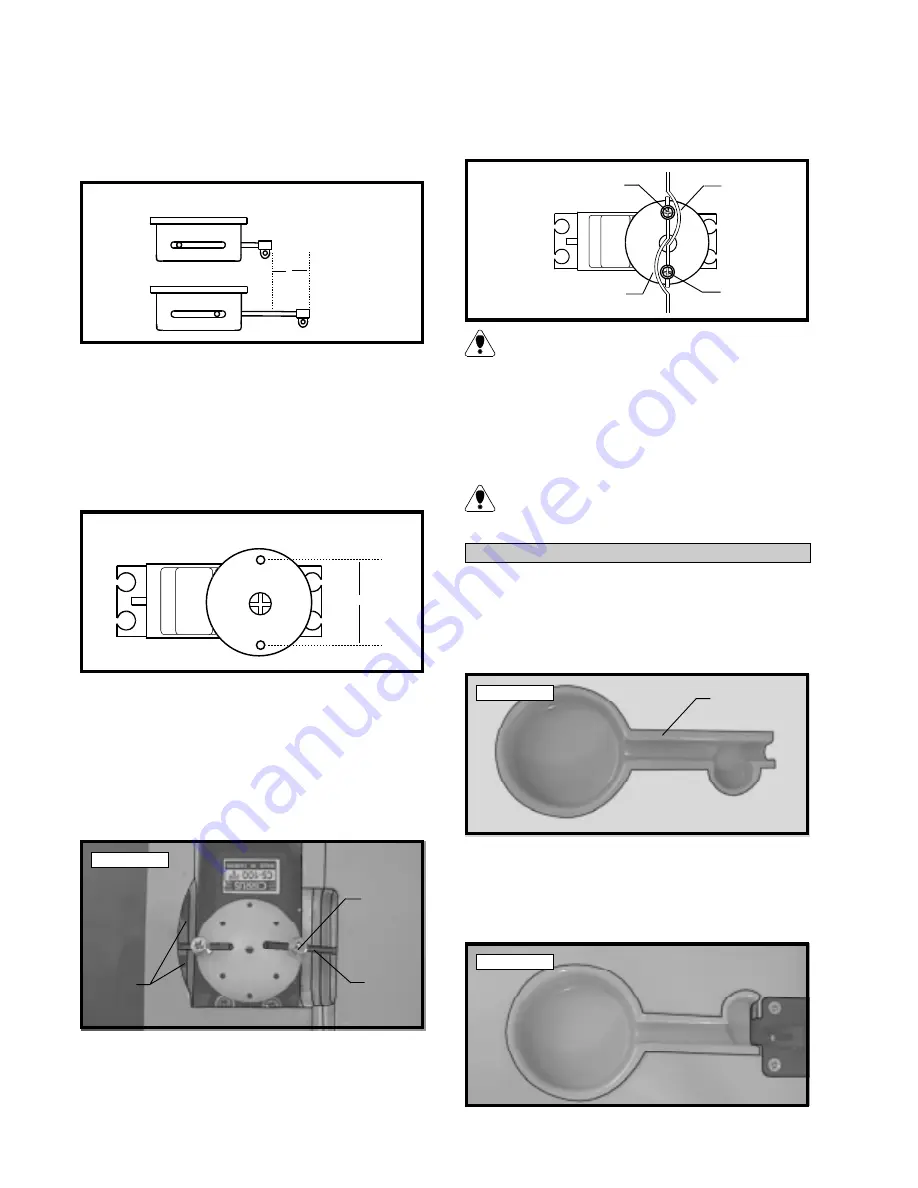

11) Using a ruler, measure the distance your re-

tract mechanism moves from the full up and locked

position to the full down and locked position. For

most retracts this measurement should be about 1”.

See figure # 5 below.

Figure # 5

q

12) To secure the two pushrod wires to the servo

wheel, we suggest using EZ Connectors. For the

mechanism to work properly the EZ Connectors need

to be installed on the servo wheel the exact distance

apart as the distance your retract mechanism travels.

You may need to drill your own holes through the

servo wheel if there are no predrilled holes that fit the

proper measurement. See figure # 6 below.

Figure # 6

q

13) With the EZ Connectors installed on the

servo wheel slide the threaded wires through the con-

nectors. With the gear in the full UP and locked posi-

tion, attach the servo wheel to the servo so that the

EZ Connectors and wires are opposite each other. If

necessary, use a modeling knife and remove a por-

tion of the top sheeting to allow clearance for the servo

wheel and connector. See photo # 13 below.

Photo # 13

q

14) Double check that the retracts are in the full

up and locked position. Tighten the set screws in the

EZ Connectors and cut off the excess wires, leaving

5/16” beyond each EZ Connector as shown above.

q

15) Rotate the servo wheel 180º so the retracts

are in the full down and locked position. Use pliers

and carefully bend each of the wires to prevent them

from hitting the EZ Connectors. See figure # 7 below.

Figure # 7

When you make the bend in the two wires, this

will shorten the wires slightly. You may need to

readjust the length of the wires using the EZ Connector.

q

16) Rotate the servo wheel back and forth to test

the operation of the retracts. If any binding is present

make small bends or adjustments in the linkage.

It is important that the retract linkage operates

smoothly. Any binding can cause the retract

servo to stall and result in excessive battery drain.

INSTALLING THE RETRACT GEAR COVERS

q

17) Using Lexan Canopy Scissors or a model-

ing knife, cut out both plastic retract gear covers, leav-

ing about a 1/8” lip around the entire perimeter to use

as a gluing surface. Cut the two gear covers apart in

the center. See photo # 14 below.

Photo # 14

q

18) Test fit the two gear covers in place on the

wing. They should fit inside the gear cutout and the

lip should rest flush on the wing surface. You may

have to make minor adjustments to fit your particular

retract installation. See photo # 15 below.

Photo # 15

X

X = Distance of

Actuator Arm

Travel

X

X = Measurement From Step # 11

EZ

Connector

Pushrod

Wire

Remove

Sheeting

Make

Bend

Make

Bend

EZ

Connector

EZ

Connector

1/8” Lip for

Gluing Surface