14

5

I

NSTALLATION

I

NSTRUCTIONS

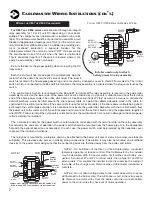

The

Cablemaster

system must be mounted in a loca-

tion that is protected from the marine environment and is certified

“ignition protected” for placement in engine rooms. For ideas on

specific locations for your boat, contact our service engineer.

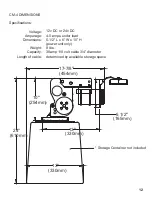

Using the drawing included with your manual, mark the mounting

location of the hawse pipe. Before drilling or cutting, check once

again to be certain that the area behind the hawse pipe is free of

wires, plumbing or structural supports for the boat. The mounting

surface should be a minimum 1/2” thick. The proper thickness can

be achieved by using a butt block of marine grade plywood behind

the mounting surface.

Cut the hawse pipe’s 3-5/8” center hole and drill the four 1/4”

mounting holes. Using a good quality marine beading compound,

secure the hawse pipe to the boat using the four (4) 1/4 x 20 x 1”

stainless steel machine screws, washers, nuts and gasket supplied

with the

Cablemaster

or use longer fasteners that are available

locally.

The power unit may now be mounted to the hawse pipe using the

angle link, the hawse pipe clamp, and U-bolts. In remote power unit

installations, the 3” schedule 40 PVC pipe is secured to the power

unit using the same standard components adding also the acces-

sories for horizontal pipe extension in order to connect the PVC pipe

to the hawse pipe (see Fig. 3 previous page).

Unless the shore power cable is being directed vertically through

a PVC pipe, you are now ready to wire the

Cablemaster

to the

boat’s DC electrical system. If the shore power cable is being direct-

ed vertically through PVC pipe (see drawing below) it is necessary

to relocate the guide roller assembly with the out-limit switch from

the bottom of the power unit to the lower end of the PVC pipe. Wires

of appropriate length will have to be spliced into the system to insure

the operation of the out-limit switch. A guide roller assembly without

the out-limit switch, included in the vertical pipe extension accesso-

ry, must be installed between the power unit and the PVC pipe to

provide trouble free operation (see accessory page).

C

Ø 3 5/8"

x4

Ø 17/64"

HI

NG

E

65002

SP

AC

E

RS

H

A

W

S

E

FL

A

NG

E

7

0

4

2

7

HI

NG

E

BO

L

T

744

1

0

AC

O

R

N

N

U

T

0

4

8

00

P

O

W

E

R

S

W

I

T

C

H

ASS

E

M

B

L

Y

(incl.

swit

ch,

cover

,

3f

t.

wire)

8

5

4

1

4

L

I

P

R

O

LL

E

R

50

4

1

6

P

U

LL

E

Y

-

IN

S

I

D

E

H

A

LF

50

4

1

7

P

U

LL

E

Y

-

O

U

T

S

I

D

E

H

A

LF

50

4

1

6

O

FF

S

E

T

P

L

A

T

E

(incl

ud

e

d

wit

h

0

4

0

4

6

a

ss

y

.)

0

4

0

4

6

G

U

I

D

E

R

O

LL

E

R

ASS

E

M

B

L

Y

(incl.

g

u

i

d

e,

rollers

4

X

,

of

fset

p

l

a

te)

7

5

4

1

2

#9

W

OO

D

R

U

FF

K

E

Y

50005

C

O

NNE

C

TO

R

L

IN

K

50

4

2

1

H

A

W

S

E

P

I

P

E

C

L

A

M

P

0

4

05

3

H

A

W

S

E

P

I

P

E

C

L

A

M

P

ASS

Y.

0

4

050

H

A

W

S

E

P

I

P

E

ASS

E

M

B

L

Y

(incl.

h

a

wse

p

i

p

e

wit

h

fl

a

n

g

e,

hin

g

e,

c

a

p

)

0

4

05

1

HI

NG

E

&

CAP

ASS

E

M

B

L

Y

50

4

2

1

HI

NG

E

50

4

20

CAP

R

E

L

A

Y

ASS

E

M

B

L

Y

0

4

0

3

4

--

1

2

/

2

4

V

O

L

T

S

7

0005

U

-

BO

L

T

(

2

X

)

6500

1

S

p

a

cer

50

4

1

5

C

H

ASS

I

S

C

O

V

E

R

50

4

1

4

C

H

ASS

I

S

0

4

8

1

2

IN

-

L

I

M

I

T

S

W

I

T

C

H

ASS

Y.

(incl.

swit

ch,

2

ft.

wire

a

ss

y

.,

p

rot

ect

ive

b

oot

)

0

4

83

0

IN

-

L

I

M

I

T

S

W

I

T

C

H

ASS

Y.

(incl.

h

a

wse

p

i

p

e

rin

g

)

8

6

4

02

CAP

G

AS

K

E

T

6000

1

H

A

W

S

E

P

I

P

E

R

ING

8

6

4

0

3

H

A

W

S

E

P

I

P

E

G

AS

K

E

T

7

0

4

3

2

A

LL

EN

SCR

E

W

0

4

8

2

4

O

U

T

L

I

M

I

T

S

W

I

T

C

H

ASS

E

M

B

L

Y

(incl.

(

2

)

swit

ches,

2

ft.

wire

a

ss

y

.)

8

74

0

4

C

H

ASS

I

S

G

AS

K

E

T

M

OT

O

R

ASS

E

M

B

L

Y

(incl.

d

rive

g

e

a

r

a

n

d

m

o

u

nt

in

g

screws)

0

4

0

3

5

--

1

2

V

O

L

T

S

0

4

0

3

6

--

2

4

V

O

L

T

S

8

6

4

0

1

H

A

W

S

E

P

I

P

E

G

AS

K

E

T

0

4

05

1

CAP

&

HI

NG

E

ASS

E

M

B

L

Y

9

000

4

P

O

W

E

R

S

W

I

T

C

H

C

O

V

E

R

C

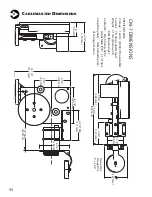

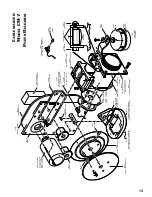

a

b

leM

a

st

er

Mo

d

el

C

M

7

P

a

rts

D

i

a

g

r

a

m

G

len

d

innin

g

M

a

rine

P

ro

du

ct

s,

I

nc.

STEP 1

Use template

on back

cover of

manual

STEP 2

Mount Hawse

pipe in hole

Hole cut in

step 1

STEP 3

Mount Hawse pipe

to power unit

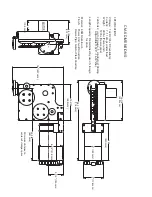

Red 1

White 2

Black 3

Power

Switch

Pos. +

Neg. -

12 / 24v

DC Input

Motor

Output

CABLEMASTER RELAY ASSEMBLY

# 04034 (12, 24 volt DC)

12v DC use 20 amp breaker

24v DC use 5 amp breaker

OUT

OUT

Limit

Switch

Switch

(Remote - RED)

(Remote - BLACK)

Orange

Black

GLENDINNING MARINE PRODUCTS, INC.

Conway, SC 843-399-6146

4

4

5

5

6

7

IN

Limit

Switch

(Rmt - Green or Tan)

(Rmt - Yellow or Purple)

ORANGE

BLACK

OFF

OUT

IN

POWER

SWITCH

RED

WHITE

BLACK

IN-LIMIT

SWITCH

OUT-LIMIT

SWITCH

M

12

!

or

!

24v

MOTOR

BATERY

!

POSITIVE

!

(+)

BATTERY

!

NEGATIVE

!

(-)

WHITE

RED

BLACK

STEP 4

Connect power to

Cablemaster relay

S

TEP

1: M

ARK

M

OUNTING

L

OCATION FOR

H

AWSE

P

IPE

S

TEP

2: C

UT

C

ENTER

H

OLE

& M

OUNT

H

AWSE

P

IPE

S

TEP

3: M

OUNT

P

OWER

U

NIT TO

H

AWSE

P

IPE

S

TEP

4: W

IRE

C

ABLEMASTER TO

E

LECTRICAL

S

YSTEM

Vertical

Extension

Relocate guide roller assembly

with out-limit switch to end of

PVC pipe extension

C

A

B

L

EM

A

S

TER

M

ODEL

CM

-7

P

AR

T

S

D

IA

G

RA

M