P

OWER

C

ABLE

I

NSTALLATION

Before installing the power cable into the

Cablemaster

, stretch the cable out in a straight line on a smooth surface to

remove any kinks or unnatural coils. Feed the “blunt cut” end of the cable into the power unit. Retract the power cable,

using the power switch or manually. Before connecting the power cable to boat’s AC electrical system, secure the nylon

safety collar and refer to the Cable Adjustment section below to pre-adjust the pulley to the proper cable size and to insure

trouble-free operation of your

Cablemaster

. The power cable should be firmly strapped down, using metal or heavy duty

plastic wiring straps, to the bottom of the cable storage area so that in no way will the

Cablemaster

pull on the power

cable’s electrical connection.

In actual usage of your

Cablemaster

, you will find

that the power cable is seldom payed out completely.

Because of this, it is advisable to occasionally pay out

the cable completely and allow the cable to recoil into its

natural coil.

The power cable must be connected to your boat’s

AC electrical system in accordance with the instructions

contained in the National Electrical Code. Care should

be taken when adjusting the out-limit collar to ensure

that no strain will be placed upon the power cable con-

nection to the electrical system.

E

C

ABLE

A

DJUSTMENT

Shore power cable diameters vary from one cable manufacturer

to another, the

Cablemaster’s

main pulley is split in half and proper

friction adjustment between the cable and main pulley is necessary

at the time of installation. Too tight adjustment will overload the

motor. On the other hand, too loose an adjustment will result in slip-

page of the cable or no movement of the cable.

The

Cablemaster

should be able to pay in and out the cable

without any slippage or any undue strain depending on the installa-

tion, and distance from the Hawse Pipe to the Cablemaster. Some

assistance will be required when extending power cord on long

extension runs or multiple bend installations. Retracting the power

cord should not be any problem.

To adjust the friction between the main pulley and the power

cable follow the instructions below:

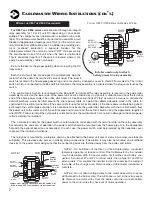

1) Remove the 1/4” nuts and lockwashers from the face of the

main pulley and remove the outer pulley half.

2) Remove or add* only equal amounts of spacers for each bolt.

3) Replace the pulley half and secure the nuts.

*When adjusting pulley friction, only add (decreases tension) or

remove (increases tension) one (1) spacer from each bolt before

checking the unit for the correct pulley friction. One spacer makes a

substantial difference in cable tension.

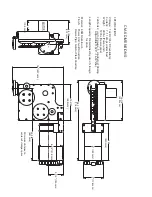

F

Remove 4 nuts &

lockwashers on face

of Main pulley

SIDE VIEW

REAR VIEW

Remove outer half of

Main pulley

Add or remove

spacers from each (4)

bolts

8

11

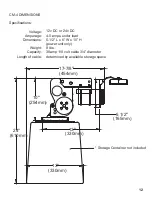

SPECIFIC

AT

IONS

Vo

ltage:

12v DC (24/32v DC a

va

ilable)

C

ur

re

n

t:

7-9

A

mps

under load

W

ei

gh

t:

21

lbs

. (p

o

we

r unit)

8

lbs

. (ha

w

se

pip

e)

Ca

b

le

siz

e:

6/4,

50

amp

, 220 v

A

djustable

(7/8”

-

1-1/4”

dia.)

Le

n

gth

c

apacit

y: D

et

er

mined

b

y siz

e

of st

or

age

lo

cat

ion

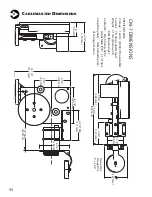

CM-7

DIMENSIONS

5

"

5"

(127 mm)

Ha

w

se P

ip

e

Fl

ange

D

im.

5"

x 6 1

/2"

3 1/2"

(89

mm)

4

3/4"

(121

mm)

9 3/4"

(248 mm)

15 3/4"

(400 mm)

6 1/4"

(159 mm)

3"

(76 mm)

3 3/4"

(95 mm)

4 1/4"

(108 mm)

8 1/8"

(206 mm)

6 3/4"

M

in

(171

mm)

13" M

in.

(330 mm)

6

1/2"

(165

mm)

12 1/4"

(311 mm)

C

ABLEMASTER

D

IMENSIONS

K