1.0

INTRODUCTION

1. The appliances incorporate a microprocessor based, fully

modulating air/gas ratio control system with direct burner

ignition. This provides a modulated heat output to either

central heating (CH) or domestic hot water (DHW) demands,

with internal frost protection provided as standard. The heat

exchanger is constructed from stainless steel encased in high

temperature polymer.

A combined circulating pump, diverter valve and automatic air

vent assembly, pressure gauge, safety valve and system

expansion vessel are included.

Isolation valves are fitted to the service connections. The

appliances have a DHW flow detection device, which gives

priority to DHW demand and proportions the required heating

load to the DHW flow rate. An electro-mechanical 24 hour

time clock is also fitted as standard.

The boiler has a pump over run feature therefore the central

heating system must include either a proprietary automatic

bypass valve or a radiator must be fitted with lock shield

valves. A separate CH expansion vessel is not required if the

total CH system content is less than 84 litres. However one is

required for systems with volumes greater than 84 litres; refer

to section 6.5. A separate DHW expansion vessel is not

required. It is recommended that a drain cock is fitted at the

lowest point in the system.

6

© Dimplex Boilers 2008

1.5

DESCRIPTION

RF room thermostats etc, are available as optional extras.

The integral clock may be removed, however the hole in the

fascia must be covered using a fascia blanking panel

(part no. 300635).

2. The boiler is set to give a maximum output of:-

24kW Model

- 24kW DHW

19.7kW CH (condensing)

30kW Model

- 30kW DHW

25.4kW CH (condensing)

38kW Model

- 38kW DHW

32kW CH (condensing)

3. It is designed for use on Natural Gas (G20). A natural gas to

propane conversion kit is available for each Dimplex Combi.

4. The boiler is suitable for use only on fully pumped sealed

heating systems. Priority is given to domestic hot water.

5. The boiler data badge gives details of the model, serial

number and Gas Council number and is situated on the inner

door panel. It is visible when the case front panel is lowered.

(Fig. 1)

6. The boiler model name and serial number are also shown on

the information label on the inside of the fascia. This is for

user reference.

7. The boiler is intended to be installed in residential /

commercial / light industrial E.M.C. environments on a

governed meter supply only.

8. The boiler must be installed with one of the purpose

designed flues such as the standard horizontal telescopic flue

kit, part no. 956120.

9. A

All systems must be thoroughly flushed and treated with

inhibitor (see section 6.2).

1.6

OPTIONAL EXTRAS

• Boiler

• Wall fixing jig

• Templates & ‘Quick Fit’ Guide

• Literature Pack

• Filling Loop

• Plugs and screws

1.7

PACK CONTENTS

1.4

SAFE MANUAL HANDLING

1. The boiler should be handled and lifted by two people.

Wear appropriate Personal Protection Equipment e.g. protective

gloves, safety footwear etc.

Plan your route to minimise the number of turns needed to

handle/lift the boiler.

2. Where possible transport the boiler using a sack truck or

other suitable trolley. Try to avoid steps, wet or slippery

surfaces, unlit areas etc. and take special care on ladders/into

lofts.

3. When handling or lifting always use safe techniques - keep

your back straight, bend your knees. Don’t twist - move your

feet, avoid bending forwards and sideways and keep the load

as close to your body as possible.

4. Asses the risks associated with handling and lifting

according to the conditions on site. If in doubt seek advice

before proceeding. Health and Safety is the responsibility of

everyone.

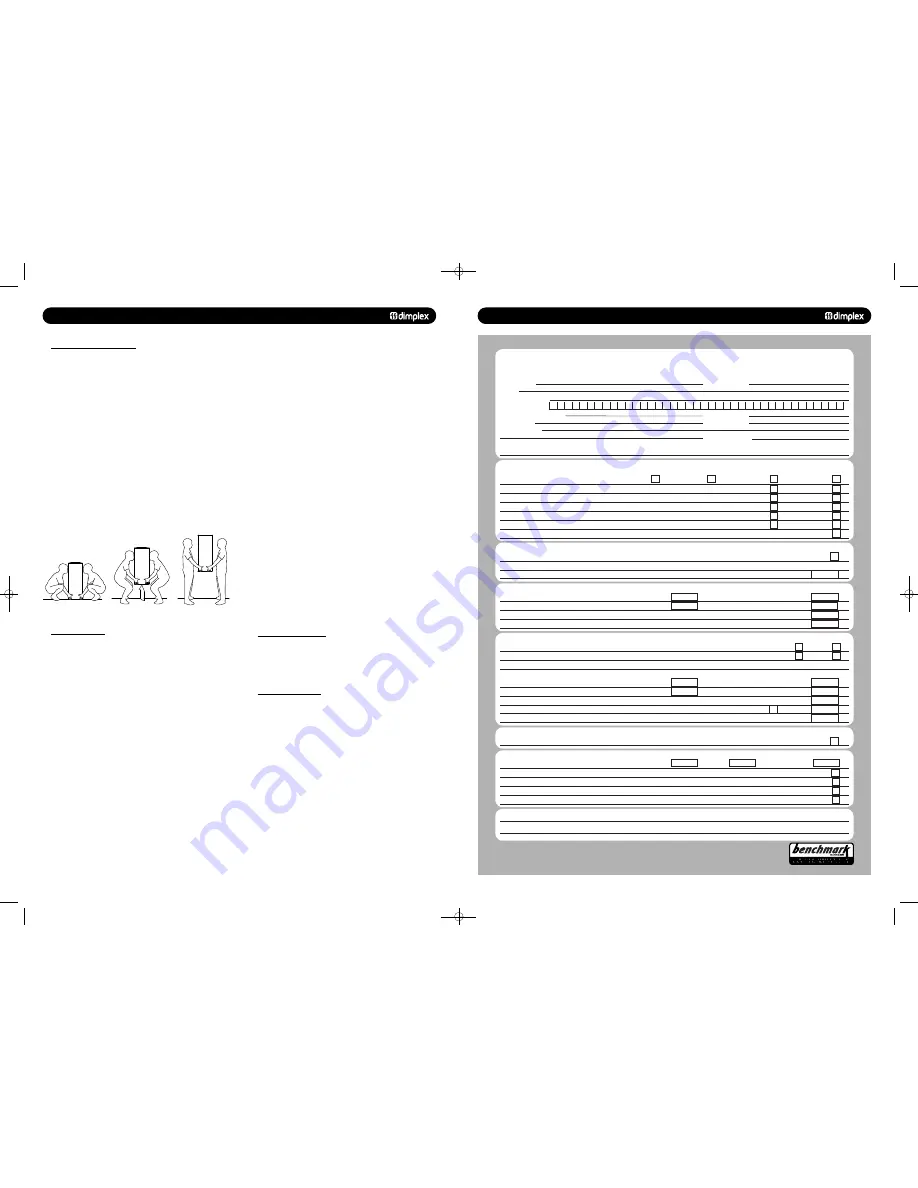

17.0

BENCHMARK

© Dimplex Boilers 2008

43

GAS BOILER SYSTEM COMMISSIONING CHECKLIST

CONTROLS

Tick the appropriate boxes

Time and Temperature Control to Heating

Room Thermostat and

Programmable

Load/Weather

Optimum

Start

Programmer/Timer

Room Thermostat

Compensation

Control

Time and Temperature Control to Hot Water

Cylinder Thermostat and Programmer/Timer

Combination Boiler

Heating Zone Valves

Fitted

Not Required

Hot Water Zone Valves

Fitted

Not Required

Thermostatic Radiator Valves

Fitted

Not Required

Automatic Bypass to System

Fitted

Not Required

Boiler Interlock

Provided

ALL SYSTEMS

The system has been flushed and cleaned in accordance with BS7593 and boiler manufacturer’s instructions

Yes

What system cleaner was used?

What inhibitor was used?

Quantity

litres

CENTRAL HEATING MODE

Measure and Record:

Gas Rate

m

3

/hr

OR

ft

3

/hr

Burner Operating Pressure (if applicable)

mbar

OR

Gas Inlet Pressure

mbar

Central Heating Flow Temperature

°C

Central Heating Return Temperature

°C

COMBINATION BOILERS ONLY

Is the installation in a hard water area (above 200ppm)?

Yes No

If yes, has a water scale reducer been fitted?

Yes

No

What type of scale reducer has been fitted?

DOMESTIC HOT WATER MODE Measure and Record:

Gas Rate

m

3

/hr

OR

ft

3

/hr

Burner Operating Pressure (at maximum rate)

mbar

OR

Gas Inlet Pressure (at maximum rate)

mbar

Cold Water Inlet Temperature

°C

Hot water has been checked at all outlets

Yes

Temperature

°C

Water Flow Rate

l/min

CONDENSING BOILERS ONLY

The condensate drain has been installed in accordance with the manufacturer’s instructions and/or BS5546/BS6798

Yes

ALL INSTALLATIONS

If required by the manufacturer, record the following

CO

2

% OR CO

ppm

OR CO/CO

2

Ratio

The heating and hot water system complies with the appropriate Building Regulations

Yes

The boiler and associated products have been installed and commissioned in accordance with the manufacturer’s instructions

Yes

The operation of the boiler and system controls have been demonstrated to and understood by the customer

Yes

The manufacturer’s literature, including Benchmark Checklist and Service Record, has been explained and left with the customer

Yes

*

All installations in England and Wales must be notified to Local Authority Building Control (LABC) either directly or through a Competent Persons Scheme.

A Building Regulations Compliance Certificate will then be issued to the customer.

©Heating and Hotwater Industry Council (HHIC)

www.centralheating.co.uk

Commissioning Engineer’s Signature

Customer’s Signature

(To confirm satisfactory demonstration and receipt of manufacturer’s literature)

This Commissioning Checklist is to be completed in full by the competent person who commissioned the boiler as a means of demonstrating

compliance with the appropriate Building Regulations and then handed to the customer to keep for future reference.

Failure to install and commission this equipment to the manufacturer’s instructions may invalidate the warranty but does not affect statutory rights.

Customer Name

Telephone Number

Address

Boiler Make and Model

Boiler Serial Number

Commissioned by

(print name)

CORGI ID Number

Company Name

Telephone Number

Company Address

Commissioning Date

To be completed by the customer on receipt of a Building Regulations Compliance Certificate

*

:

Building Regulations Notification Number

(if applicable)

48pp MANUAL SPREADS 19/10/10 08:36 Page 6