7.0

SITE REQUIREMENTS

7.6

CONDENSATE DRAIN

NOTE: The appliance is fitted with a trap the depth of

which is >= 75mm, therefore no other traps are required in

the condensate run.

The condensation discharge pipe must not rise at any point

along its length. There MUST be a fall of AT LEAST 2.5° (50mm

per metre) along the entire run.

1. The condensate outlet will accept 21.5mm (

3

/

4

in) plastic

overflow pipe which should discharge internally into the

household drainage system, downstream of all other traps. if

this is not possible, discharge into an outside drain is

acceptable.

2. Ensure the discharge of condensate complies with any

national or local regulations in force.

BS 6798:2000 & Part HI of the Building Regulations give

further guidance.

3. Metal pipework is NOT suitable for use in condensate

discharge systems.

4. The pipe should be a minimum of 21.5mm diameter and

must be supported properly.

5. IIt is advisable to keep the condensate pipe internal.

6. E

External runs greater than 3 metres or runs in cold areas

should use 32mm waste pipe.

7. If the boiler is fitted in an unheated location the entire

condensate discharge pipe should be treated as an external

run.

8. In all cases discharge pipe must be installed to aid disposal

of the condensate.

9. When discharging condensate into a soil stack or waste pipe

the effects of existing plumbing must be considered. If soil

pipes or waste pipes are subjected to internal pressure

fluctuations when WC’s are flushed or sinks emptied then

back-pressure may force water out of the boiler trap and

cause appliance lockout.

Examples are shown of the following methods of

terminations:-

i) to an internal soil & vent pipe

ii) via and internal discharge branch (e.g. sink waste)

iii) to a drain or gully

iv) to a purpose made soakaway

10. In exceptional circumstances, such as when a boiler is

installed in a basement without drainage, it may be necessary

to install a condensate pump to carry condensate up to ground/

drain level. Such products are available from most plumbing

merchants. For help with selecting a condensate pump contact

Dimplex Boilers - Tel: 0844 3711121.

WARNING: There must be no air breaks in the condensate

pipework or drainage system.

16

© Dimplex Boilers 2008

50mm per metre of pipe r

un

2.5° Minimum fall

450mm min

Termination to an internal soil and vent pipe

50mm per metre of pipe r

un

2.5° Minimum fall

External termination via internal discharge branch

e.g sink waste - downstream

Sink

Pipe must terminate

above water level but

below surrounding surface.

50mm per metre of pipe r

un

2.5° Minimum fall

Termination to a purpose made soak-away

Holes in the soak-away must

face away from the building

500mm min

NOT ALLOWED

There should be

no air gap

Fig. 14

Fig. 15

Fig. 17

Fig. 16

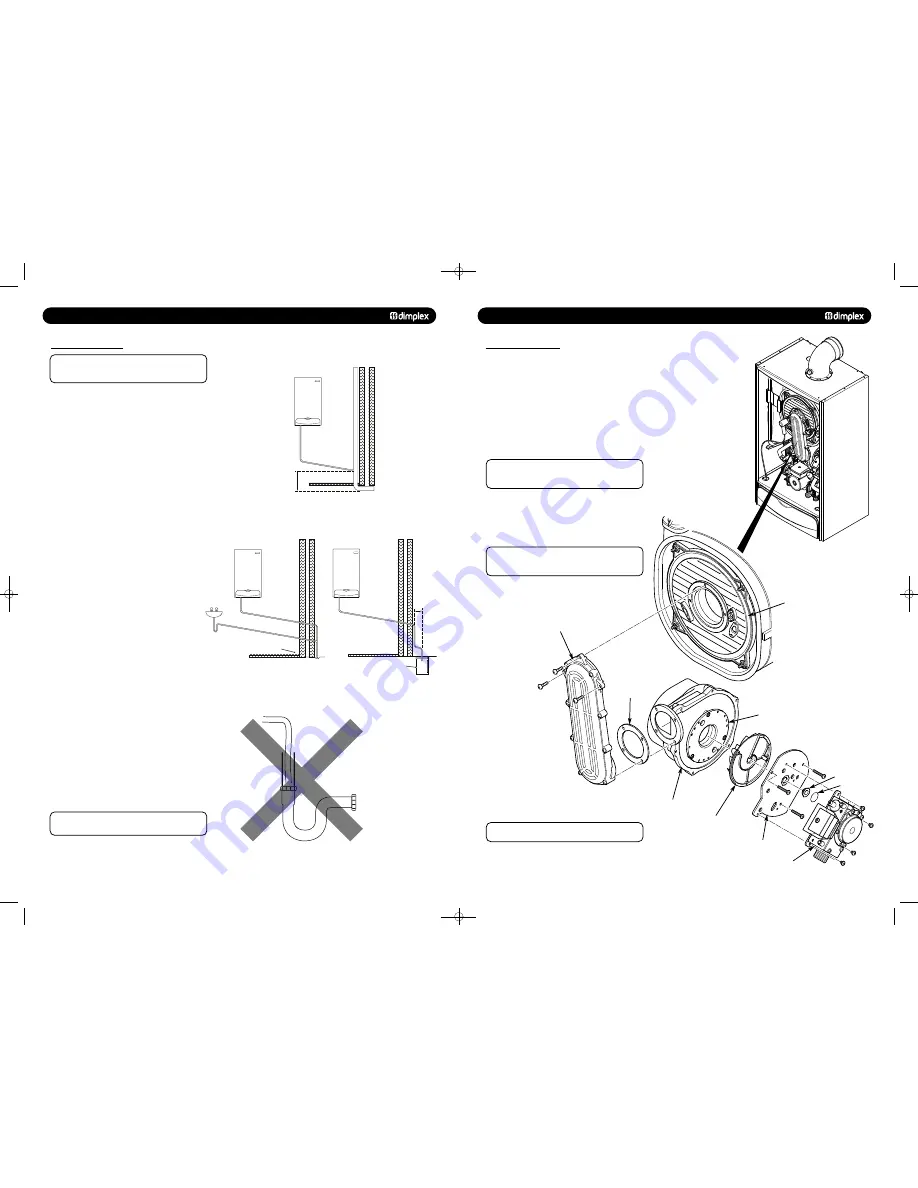

13.0

CHANGING COMPONENTS

13.3

GAS VALVE AND FAN

1. Disconnect the two leads to the fan and one lead to the gas

valve.

2. Undo the nut on the gas inlet pipe to the valve and retain

the sealing washer.

3. Remove the three securing screws holding the air/gas

Channel to the burner door plate and remove the valve and fan

assembly (Fig. 57).

4. Remove the three screws holding the valve and swirl plate

to the fan adaptor plate.

NOTE: Mark on the adaptor plate which holes are being

used by the screws. Using the wrong holes on

re-assembly will cause mis-alignment of the gas valve.

Fan Only

6. Remove the three screws holding the fan adaptor to the fan.

7. Remove the four screws securing the fan to the air/gas

channel. Reassemble in reverse order ensuring all seals are in

place.

NOTE: The gas valve throttle should be adjusted in

accordance with the instructions supplied in the spares kit

See Section 10.

© Dimplex Boilers 2008

33

NOTE: Dimplex Combi 38 will also be fitted with a black

plastic air cowl which encases the swirl plate.

Fig. 57

Swirl Plate

Fan

Fan Gasket

Burner Door

Air/Gas Channel

Fan Adaptor Plate

Injector Plate

Injector

Injector ‘O’ Ring

Gas Valve

48pp MANUAL SPREADS 19/10/10 08:36 Page 16