Page 34

Page 35

SERVICING AND MAINTENANCE

SERVICING AND MAINTENANCE

FAULT FINDING

FAULT FINDING

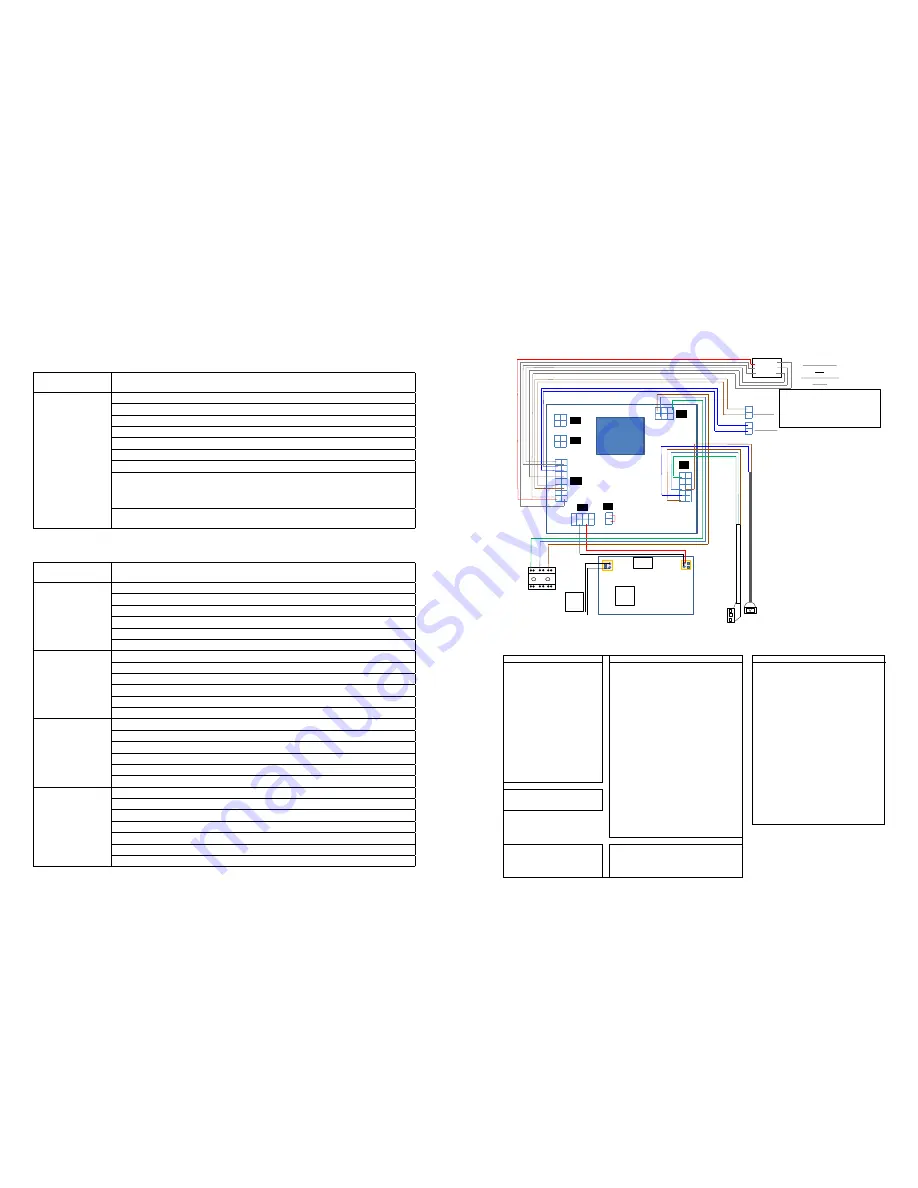

Electrical power connections

Check inputs to the PWM Controller PCB

Reference schematic

opposite

Check procedure

Power supply to PWM

Controller PCB

Electrically isolate power supply at fused spur switch and remove fuse.

Earth continuity test (dead test) – to ensure that the appliance is earthed

Mains voltage test (dead test) - to ensure that the appliance is isolated

Resistance to earth (dead test) – to ensure that the wiring insulation to the product is intact

Short circuit test (dead test) – to ensure that no components in the products circuit have a short circuit

Visually inspect wiring is correct as per fig 4.3

Connect supply

Polarity test (live test) - to ensure that the live is connecter to the live etc

• Check 230V ac across L1 to Earth

• Check 230V ac across L1 to N

• Check for 0 to 15V ac N to earth

Reference to “Boilerfault finder.com” gives clear instructions to on how to perform these tests. (Menu

options 1st. Boiler Fault finder 2nd. Electrical safety checks).

Reference schematic

opposite

Check procedure

CW temperature sensor

Power off

Disconnect J18

Measure and record the resistance across terminals 6 and 13

Measure the cold water inlet temperature

Compare the resistance measured with chart “Tasseron NTC 12k thermistor”

The reading should make sense taking measurement conditions into consideration

TS temperature sensor

Power off

Disconnect J18

Measure and record the resistance across terminals 3 and 10

Measure the thermal store temperature

Compare the resistance measured with chart “Tasseron NTC 12k thermistor”

The reading should make sense taking measurement conditions into consideration

HW temperature sensor

Power off

Disconnect J18

Measure and record the resistance across terminals 7 and 14

Measure the Hot water temperature

Compare the resistance measured with chart “HUBA combined flow sensor and NTC 10k thermistor”

The reading should make sense taking measurement conditions into consideration

Flow sensor

Power off

Disconnect J18

Power on Sensor required a power supply 5 VDC

Open a HW tap and set to a flow rate.

Measure and record the frequency across terminals 1 and 12

Compare the frequency measured with chart “flow rate determination”

The reading should make sense taking measurement conditions into consideration

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1

2

3

4

1

2

3

4

1

2

3

4

5

6

7

8

1

2

1

2

3

4

5

6

7

8

9

1

10

2 3

4 5 6

J18

J20

J19

J3

J7

J8

J1

TS sensor

GND GND

IN OUT

T1 T2

1

2

CW sensor

1

2

Combined flow

and

HW temperature

sensor

L - Brown

PR61

E – G/Y

N - Blue

PW

M

-

PW

M

+

SP

ARE

Fuse

Dip

Sw

itc

h

1 2 3 4

To

DHW

pipe

All the these sensor inputs carry a

Voltage of 5V.

The max cable length is 1 meter.

The sensors connected to the control

Should be free from the appliance earth

Resistance

Resistance

Ohm

°C

±°C

Ohm

°C

±°C

309396

-40

1.7

334275

-36

0.9

171840

-30

1.7

47369

-6

0.1

98932

-20

1.6

26023

5

0.1

58879

-10

1.5

11000

23

0.6

36129

0

1.4

10500

24

0.6

22804

10

1.4

10000

25

0.6

14773

20

1.3

9500

26

0.7

12000

25

1.2

9000

27

0.7

9804

30

1.2

8500

29

1.4

6652

40

1.1

8000

30

1.5

4607

50

1

7500

31

1.6

3252

60

0.9

7000

33

1.7

2337

70

1.1

6500

35

1.7

1707

80

1.3

6000

37

1.8

1266

90

1.5

5500

39

1.9

952

100

1.8

5000

41

2.1

4500

44

2.2

4000

47

2.3

3500

50

2.5

3000

54

2.7

2500

59

2.9

2000

65

3.3

1500

73

3.7

1000

86

4.3

R-nominal

R-nominal

B-value

B-value

R-Tolerance

R-Tolerance

Tmin

Tmin

Tmax

Tmax

125°C

under 25°C±0.025*T °C over 25°C±0.05*T °C

Huba combined flow sensor and NTC 10k thermistor

Tasseron NTC 12k thermistor

12Kohm @25°C

B3740K

3%@60°C

150°C

Temperature

Temperature

-40°C

-40°C

Used on the store temperature sensors and the

cold water inlet temperature sensors

12Kohm @25°C

B4050K

Flow volume determination

(Full range 1.8 to 32.0 l/min, restricted to 26. 5 l/min)

HZ

L/min HZ

L/min HZ L/min

25 1.9 125 10.4 225 18.8

30 2.3 130 10.8 230 19.2

35 2.8 135 11.2 235 19.7

40 3.2 140 11.6 240 20.1

45 3.6 145 12.1 245 20.5

50 4.0 150 12.5 250 20.9

55 4.4 155 12.9 255 21.3

60 4.9 160 13.3 260 21.8

65 5.3 165 13.7 265 22.2

70 5.7 170 14.2 270 22.6

75 6.1 175 14.6 275 23.0

80 6.6 180 15.0 280 23.5

85 7.0 185 15.4 285 23.9

90 7.4 190 15.9 290 24.3

95 7.8 195 16.3 295 24.7

100 8.3 200 16.7 300 25.2

105 8.7 205 17.1 305 25.6

110 9.1 210 17.5 310 26.0

115 9.5 215 18.0 315 26.4

120 9.9 220 18.4 320 26.8

Summary of Contents for Torrent Stainless OV

Page 22: ...Page 42 Page 43 NOTES NOTES ...