Page 14

Page 15

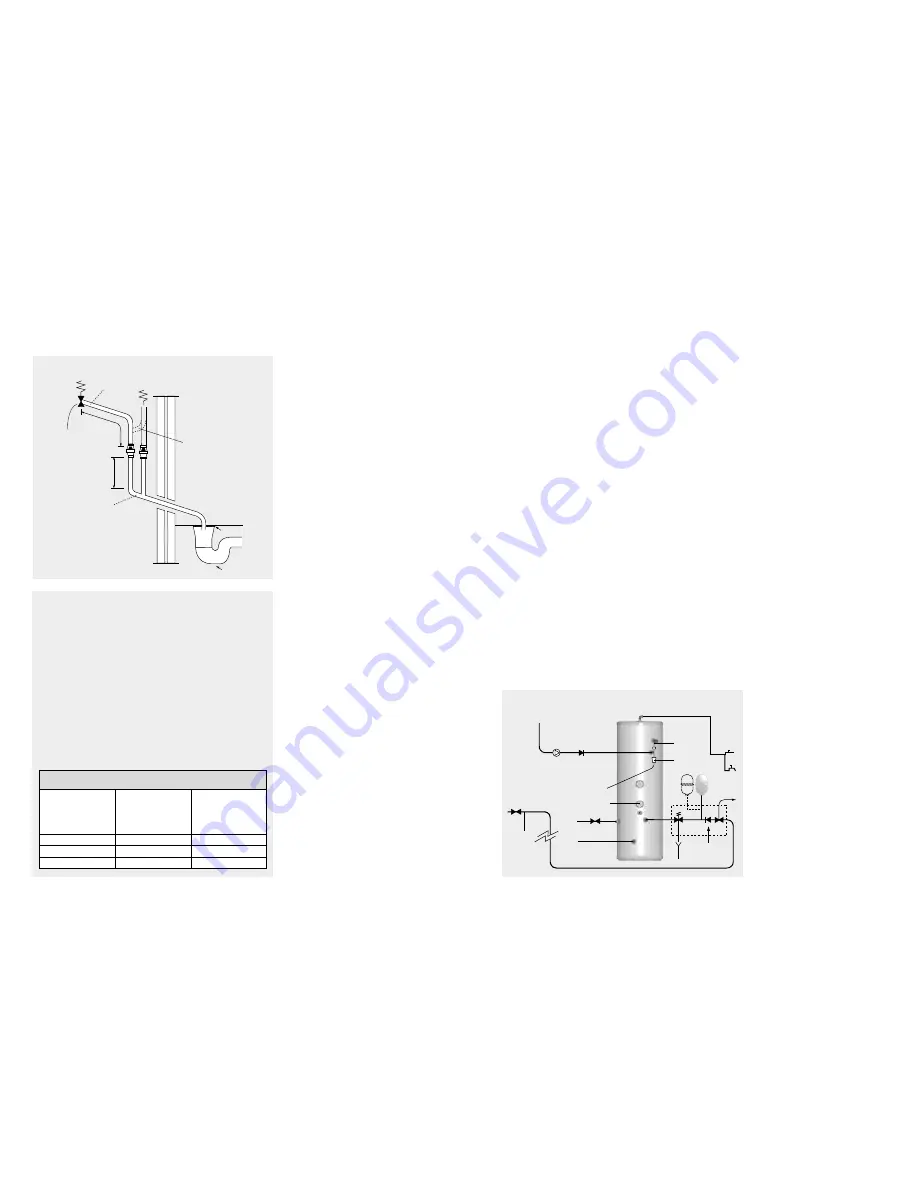

15 mm

discharge

pipe

Expansion

relief valve

Typical Discharge Pipe Arrangement

Dotted line showing

alternative route with

single tundish being used

600 mm max.

P & T

Relief

Valve

300 mm

min.

22 mm metal pipe with continuous

fall up to 9m equivalent length (D2).

NOTES:

The discharge will consist of scalding

water and steam. Asphalt, roofing felt

and non-metallic rainwater goods may

be damaged by such discharges.

It is not acceptable to discharge straight

into a soil pipe.

Discharge below

fixed grating

Fixed Grating

Trapped gully

Pressure & Temperature/expansion Relief

Valve Pipework

The relief valve should be installed to discharge

in accordance with G3 of the Approved

Document of the Building Regulations and

should be piped to where it is visible, but will

not cause danger to persons or damage to

materials.

The following information is taken from

Approved Document G3 of the Building

Regulations and is provided to assist with

the design and installation of the discharge

pipework. However, the information is not

exhaustive and reference should always be

made to Approved Document G3 of the Building

Regulations. The final decision regarding any

arrangements rests with Building Control and

it is recommended that their advice is sought

if you have any concerns regarding this aspect

of the installation.

The two safety valves will only discharge

water under fault conditions. When operating

normally water will not be discharged.

The tundish should be vertical, located in the

same space as the unvented hot water storage

system and be fitted as close as possible and

within 600mm of the safety device e.g. the

temperature relief valve.

The discharge pipe (D2) from the tundish should

terminate in a safe place where there is no risk

to persons in the vicinity of the discharge, be

of metal and:

a) Be at least one pipe size larger than the

nominal outlet size of the safety device unless

its total equivalent hydraulic resistance

exceeds that of a straight pipe 9m long

i.e. discharge pipes between 9m and 18m

equivalent resistance length should be at

least two sizes larger than the nominal outlet

size of the safety device, between 18 and

27m at least 3 sizes larger, and so on. Bends

must be taken into account in calculating

the flow resistance. Refer to the table and

the worked example.

An alternative approach for sizing discharge

pipes would be to follow BS EN 806-2:2005

Specification for design installation, testing

and maintenance of services supplying water

for domestic use within buildings and their

curtilages.

b) Have a vertical section of pipe at least

300mm long, below the tundish before any

elbows or bends in the pipe work.

c) Be installed with a continuous fall.

d) It is preferable for the discharge to be visible at both the tundish and the final point

of discharge but where this is not possible or practically difficult there should be

clear visibility at one or other of these locations. Examples of acceptable discharge

arrangements are:

1. Ideally below the fixed grating and above the water seal in a trapped gulley.

2. Downward discharges at a low level; i.e. up to 100mm above external surfaces

such as car parks, hard standings, grassed areas etc are acceptable providing that

where children play or otherwise come into contact with discharges, a wire cage

or similar guard is positioned to prevent contact whilst maintaining visibility.

3. Discharges at a high level; e.g. into metal hopper and metal down pipe with the

end of the discharge pipe clearly visible (tundish visible or not) or onto a roof

capable of withstanding high temperature discharges of water and 3m from

any plastic guttering systems that would collect such discharges.

4. Where a single common discharge pipe serves more than one system, it should

be at least one pipe size larger than the largest individual discharge pipe (D2)

to be connected.

5. If unvented hot water storage systems are installed where discharges form

safety devices may not be apparent i.e. in dwellings occupied by blind, infirm

or disabled people, consideration should be given to the installation of an

electronically operated device to warn when discharge takes place.

Safety

The safety devices supplied or fitted on an StainlessLite Plus are selected for their

suitability for the temperatures and pressures involved. They must not be changed,

removed or by-passed and it is essential that only genuine replacement parts supplied

or approved by Gledhill Building Products Limited are used. All parts are available to

approved installers from Gledhill Building Products Limited, Sycamore Estate, Squires

Gate, Blackpool (Telephone 01253 474402).

Tundish

Hot Outlet

To Drain

PRV

NRV

Stop

Tap

Kitchen

Cold

Tap

Combination

Valve

Balanced

Cold

Outlets

P&T

Relief Valve

Immersion Heater

Expansion Vessel(s)

Boiler

Return

Boiler

Flow

2 Port Valve

Secondary

Return Circuit

Schematic Diagram

Non Return

Valve

Pump

ERV

Worked Example

The example below is for G1/2 temperature relief valve with a discharge pipe (D2)

having 4 elbows and length of 7m from the tundish to the point of discharge.

From the table below:

Maximum resistance allowed for a straight length of 22mm copper discharge

pipe (D2) from a G1/2 temperature relief valve is: 9m subtract the resistance for

4 x 22mm elbows at 0.8m each = 3.2m.

Therefore the maximum permitted length equates to: 5.8m.

5.8m is less than the actual length of 7m therefore calculate the next largest size.

Maximum resistance allowed for a straight length of 28mm pipe (D2) from a G1/2

temperature relief valve equates to: 14m.

As the actual length is 7m, a 28mm (D2) copper pipe will be satisfactory.

Sizing of copper discharge pipe ‘D2’ for a temperature relief valve

with a G1/2 outlet size (as supplied)

Size of discharge

pipework

Maximum length of

straight pipe

(no bends or elbows)

Deduct the figure

below from the

maximum length for

each bend or elbow in

the discharge pipe

22mm

Up to 9m

0.8m

28mm

Up to 18m

1m

35mm

Up to 27m

1.4m

INSTALLATION

INSTALLATION

INSTALLATION

INSTALLATION

Line Strainer

This is integral within the combination inlet

group to reduce the likelihood of contaminants

fouling the valve seat. Following installation this

line strainer must be cleaned and replaced. This

needs to be carried out on a regular basis. as part

of the annual maintenance/service check.

Tundish

This is to allow the discharge from any Relief

Valve to be seen. It must be fitted away from

any electrical devices. See page 14 for discharge

pipework details.

Expansion Vessels Installation

To prevent water stagnation and particulate

accumulation affecting water quality, it is

recommended that the expansion vessel be

installed in the vertical orientation so that the

fitting accommodating thermal expansion or a

pressure surge is:-

1. bottom fed and upright; and

2. that the connecting pipework to the fitting:-

- rises continuously; and

- is kept to a minimum;

2 expansion cylinders on 400 litre Models

All 400 litre models are supplied with two 24

litre expansion cylinders. These can be coupled

together and fitted to the expansion cylinder

tapping on the combination inlet valve, or by

some other means on the cold/hot water inlet

pipework. There must be no valve on the pipe

work between the expansion cylinders and the

unvented cylinder which could prevent the

expansion of the water contained in the unvented

cylinder reaching the expansion cylinders.

Combination Inlet Group

Combines elements 1, 2 and 3 below.

1.

Pressure Reducing Valve

- The cold water

supply to any mixer taps/showers must

be taken from the cold water tapping of

this valve to ensure balanced hot and cold

pressures. This valve is factory set to ensure

the correct operating pressure for the

StainlessLite Plus.

2.

Non Return Valve

- This is integral with the

pressure reducing valve to prevent backflow of

hot water towards cold water draw off points.

3.

Cold Water Expansion Relief Valve

- This safety

device is preset at the factory and will relieve

excess cold water pressure resulting from a

fault condition.