9

To Dismantle Gear End

After removing valve casing (43) and plunger pipe (29B), drain oil. Remove crankcase cover (4) and

bearing cover (14). Loosen connecting rod screws (24A) and push the front of the connecting rod (24)

forward as far as possible into the crosshead guide.

IMPORTANT!

Connecting rods (24) are marked for identification. Do not twist connecting rod halves.

Connecting rod is to be reinstalled in the same position on shaft journals.

Turning the crankshaft (22) slightly, hit it out carefully to the side with a rubber hammer.

IMPORTANT!

Do not bend the connecting rod (24) shanks. Check crankshaft (22) and connecting rod

(24) surfaces, radial shaft seals (15) and taper roller bearings (20).

To Reassemble

Using a soft tool, press in the outer bearing ring until the outer edge lines up with the outer edge of the

bearing hole. Remove bearing cover (14) together with radial shaft seal (15) and o-ring (16). Fit crank-

shaft (22) through bearing hole on the opposite side. Press in outer bearing and tighten it inwards with

the bearing cover, keeping the crankshaft in vertical position and turning slowly so that the taper roll-

ers of the bearings touch the edge of the outer bearing ring. Adjust axial bearing clearance to at least

0.1mm and maximum 0.15mm by placing fitting discs (20A and 20B) under the bearing cover.

IMPORTANT!

After assembly has been completed, the crankshaft should turn easily with very little

clearance. Tighten connecting rod screws (24A) to 22 ft.-lbs. (30 Nm).

Pump Mounting Selection Guide

Bushings

06496

- 35mm H Bushing

Pulley & Sheaves

07165

- 12.75” Cast Iron - 4 gr. - AB Section

Rails

07357

- Plated Steel Channel Rails

(L=11.75” x W=1.88” x H=3.00”)

LP 200-SS - Repair Instructions

Summary of Contents for LP200-SS

Page 4: ...4 Exploded View LP200 SS...

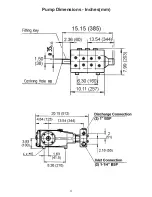

Page 11: ...11 Pump Dimensions Inches mm...