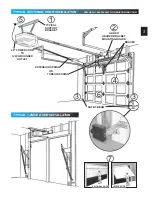

FIG. 5-1

Terminal attachments at power head.

WALL CONTROL INSTALLATION

FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

4

1. Finding the mounting location

.

•

Pick a convenient location for mounting

wall control.

–

Location you choose should be in direct sight

of door.

–

It should be at least 5' above floor to prevent

small children from operating door.

–

It must be away from any moving parts. (You

should not be able to reach the door while

standing at wall control.)

2. Wiring

.

•

Run wire from power head to wall control.

•

Securely fasten to ceiling using insulated

staples provided.

•

Split and strip ends of wire

(Fig. 4-5)

.

•

On power head:

–

Attach the

striped wire to terminal #1

and

white wire to terminal #2 (Fig. 5-1)

.

•

On back of wall control:

–

Attach

striped wire to terminal “B”

, and

white wire to terminal “W.” (Fig. 5-2)

.

3. Mounting

.

•

Fasten wall control to wall with 2 screws (33)

(Fig. 5-3)

.

•

Remove protective backing from “entrapment”

warning label

(Fig. 5-4)

.

–

Stick label on wall near wall control.

NOTE: Additional wall controls are available from

your dealer. ONLY ONE OF YOUR WALL

CONTROLS MAY BE THE LIGHTED TYPE. If you

have a lighted wall control, all your additional

controls must be un-lighted. More than one

lighted wall control per operator will cause

a malfunction.

Verify there is no power to the operator before

installing wall control wires.

WARNING

Use of any wall control other than the type

supplied will prevent the light from working and

could cause the door to operate on its own.

Cut or pinched wires can cause the wall control to

stop working. When using the insulated staples,

make sure you only pound them in as far as

needed to hold the wire snugly.

CAUTION

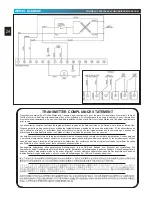

FIG. 5-2

Wall control wire attachment.

FIG. 5-3

Mounting wall control.

17

[33]

FIG. 5-4

Entrapment warning label.

button

console

1

2

#6 x 1-1/4"