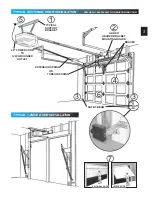

Power Head Assembly

1J

1N

1X

1L

1N

1E

1K

1D

1A

1N

1H

1B

1Q

1G

1D

1F

49

1P

1M

1N

7

Item Part Name

Number Required

1 pc. rail

3 pc. rail

1

Power head assembly

(box)

1

1

2

Rail assembly (1-piece)

(box)

1

3

Rail (1-piece)

(box)

1

4

Rail assembly (3-piece)(items 5, 6, 7)

(box)

1

5

First rail section

(box)

1

6

Middle rail section

(box)

1

7

End rail section

(box)

1

8

Rail clamp

(blue bag)

4

9

1/4"-20 x 5/8" hex head bolt

(blue bag)

4

12

10

1/4"-20 hex flange nut

(blue bag)

4

12

11

Carriage assembly

(box)

1

1

12

Rail strap

(blue bag)

1

1

13

Limit switch OPEN (white wire)

(green bag)

1

1

14

Limit switch CLOSE (brown wire)

(green bag)

1

1

15

Release cord

(green bag)

1

1

16

Release knob

(green bag)

1

1

17

Emergency release tag

(green bag)

1

1

18

Header bracket

(orange bag)

1

1

20

Door bracket

(orange bag)

1

1

22

1/4" x 2" lag screw

(orange bag)

8

8

23

Straight door arm

(box)

1

1

24

Clevis pin

(yellow bag)

2

2

25

Cotter pin

(yellow bag)

2

2

26

Curved door arm

(box)

1

1

27

3/8"-16 x 7/8" hex head bolt

(yellow bag)

2

2

28

3/8"-16 hex flange nut

(yellow bag)

2

2

29

Wire

(box)

1

1

30

Insulated staple

(red bag)

varies/model varies/model

31

Wall button

(red bag)

varies/model varies/model

32

Wall console

(box)

varies/model varies/model

33

No. 6 x 1-1/4" pan head phillips screw

(red bag)

varies/model varies/model

34

Entrapment WARNING label

(manual)

1

1

35

Safe-T-Beam (STB) sensor (green LED)

(box)

1

1

36

Safe-T-Beam (STB) source (red LED)

(box)

1

1

37

Safe-T-Beam (STB) bracket

(yellow bag)

2

2

38

Remote operator

(box)

varies/model varies/model

39

#8-32 x 1" machine screw

(green bag)

2

2

40

Safety & maintenance guide

(manual)

1

1

41

Wire clip

(green bag)

varies/model varies/model

42

1/4"-20 x 3/4" self-drilling screw

(orange bag)

3

3

44

#10-16 x 1-1/4" phillips hex head screw

(yellow bag)

4

4

46

5/16"-18 x 3/4" hex head bolt

(orange bag)

3

3

47

5/16"-18 hex flange nut

(orange bag)

4

4

48

Mounting Straps

(box)

2

PARTS LIST

POWER HEAD EXPLODED VIEW

Item

Part Name

1

Power head assembly

1A

Cover (by series/model)

1B

Front panel assembly

1D

Motor parts

1E

Circuit board assembly

1F

Capacitor (by series/model)

1G

Opto wheel (not shown)

1H

Carriage slide

1J

Chain

POWER HEAD PARTS LIST (pre-assembled)

Garage doors are large, heavy objects that move with the help of springs under

high tension and electric motors. Since moving objects, springs under tension,

and electric motors can cause injuries, your safety and the safety of others

depend on the owner or user of this system to read, understand and implement

the information in this manual. If you have questions or do not understand the

information presented, contact The Genie Company or an authorized Genie Dealer.

In this section and those that follow, the words

Danger, Warning,

and

Caution

are used to emphasize important safety information. The word:

DANGER

means that severe injury or death will result from failure to follow

instructions.

WARNING

means that severe injury or death can result from failure to follow

instructions.

CAUTION

means that property damage or injury can result from failure to

follow instructions.

The word

NOTE

is used to indicate important steps to be followed or

important considerations.

OVERVIEW OF

POTENTIAL HAZARDS

SAFETY INFORMATION

POTENTIAL

HAZARD

EFFECT

PREVENTION

Keep people clear of opening while door is

moving.

Do Not

allow children to play with the door

operator.

Do Not

operate a door that jams or one

that has a broken spring.

MOVING DOOR

WARNING:

Can Cause

Serious Injury

or Death

Turn off power before removing operator

cover.

When replacing cover, make sure wires

are not pinched or near moving parts.

Operator must be properly grounded.

ELECTRICAL

SHOCK

WARNING:

Can Cause

Serious Injury

or Death

Do Not

try to remove, repair or adjust

springs or anything to which door spring

parts are fastened, such as, wood blocks,

steel brackets, cables or other like items.

Repairs and adjustments must be made by

a trained professional service technician

using proper tools and instructions.

HIGH

SPRING

TENSION

WARNING:

Can Cause

Serious Injury

or Death

[1]

Item

Part Name

1K

Circuit board bracket

1L

Drive module

1M

Terminal strip

1N

No. 8 x 3/4" hex washer head screw

1P

Shock absorption stop (not shown)

1Q

Motor mount bracket (not shown)

1X

Chassis

49

Lens